Safety Instrumented Systems (SIS) are among the most critical safeguards in high-risk industrial operations. When process control fails and hazards escalate, SIS acts as the last automated line of defense, preventing catastrophic incidents such as explosions, fires, toxic releases, and equipment rupture.

In industries like oil and gas, offshore FPSOs, petrochemicals, power generation, and chemical processing, a poorly designed or misunderstood SIS has contributed to major industrial accidents worldwide.

This HSSETips.com guide explains Safety Instrumented Systems (SIS) in clear, practical terms—covering what SIS is, how it works, why it matters, and how HSSE professionals should manage it.

What Is a Safety Instrumented System (SIS)?

A Safety Instrumented System (SIS) is an independent, automated protection system designed to detect hazardous conditions and take the process to a safe state when predefined limits are exceeded.

An SIS:

- Monitors critical process parameters

- Performs safety logic

- Automatically initiates protective actions

HSSE definition:

SIS reduces the risk of hazardous events to a tolerable level when normal controls fail.

Why SIS Is Critical in HSSE and Process Safety

SIS is specifically intended to prevent:

- Overpressure and vessel rupture

- Loss of containment

- Fires and explosions

- Environmental pollution

- Fatal injuries

Unlike alarms that rely on operator response, SIS acts automatically, often within seconds.

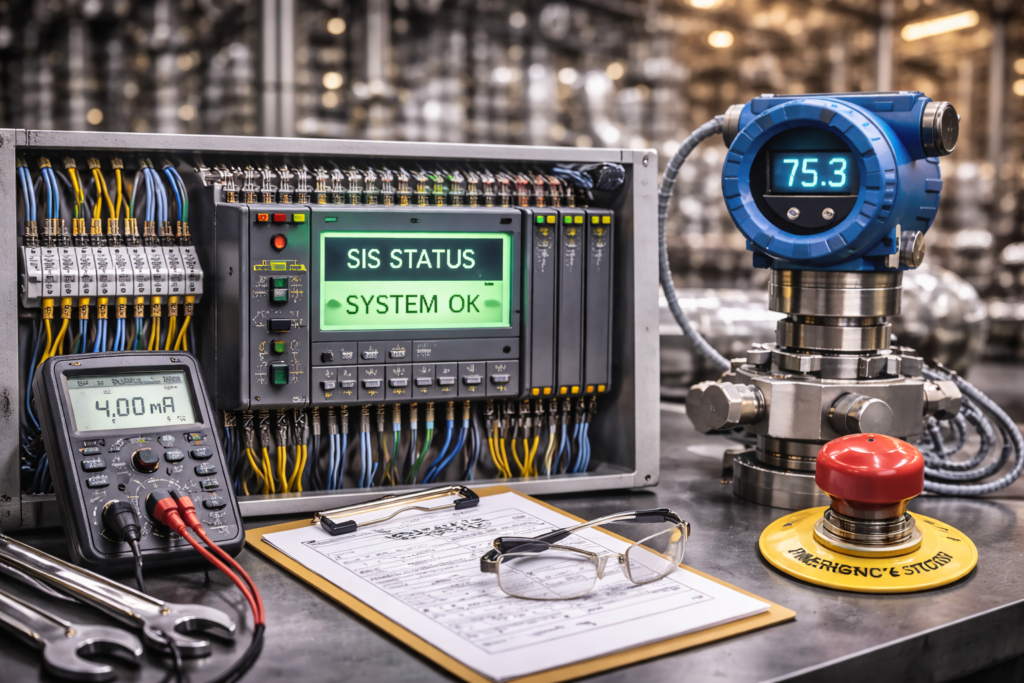

Key Components of a Safety Instrumented System

An SIS consists of three independent elements:

1. Sensors (Input Devices)

Detect abnormal conditions, such as:

- Pressure transmitters

- Temperature transmitters

- Level transmitters

- Flow transmitters

⚠️ HSSE note:

Pressure gauges and switches are generally not suitable as primary SIS sensors.

2. Logic Solver

The “brain” of the SIS that:

- Receives sensor signals

- Executes safety logic

- Decides when to trip

Examples:

- Safety PLC

- Hardwired relay logic

Logic solvers must be independent from the Basic Process Control System (BPCS).

3. Final Elements

Devices that take the process to a safe state, such as:

- Shutdown valves

- Emergency isolation valves

- Motor trip relays

- Burner shutoff systems

What Is a Safety Instrumented Function (SIF)?

A Safety Instrumented Function (SIF) is a specific safety action performed by the SIS to mitigate a defined hazard.

Example SIF

- If pressure > 50 bar → Close shutdown valve → Stop flow

Each SIF:

- Addresses one hazardous scenario

- Has a defined Safety Integrity Level (SIL)

Safety Integrity Levels (SIL) Explained

SIL defines the required reliability of a Safety Instrumented Function.

| SIL Level | Risk Reduction Factor (RRF) |

|---|---|

| SIL 1 | 10 – 100 |

| SIL 2 | 100 – 1,000 |

| SIL 3 | 1,000 – 10,000 |

| SIL 4 | >10,000 (rare in process industry) |

HSSE rule:

Higher risk → Higher SIL requirement.

SIS vs Basic Process Control System (BPCS)

| Feature | SIS | BPCS |

|---|---|---|

| Purpose | Safety | Control |

| Response | Automatic shutdown | Normal operation |

| Independence | Mandatory | Not independent |

| SIL requirement | Yes | No |

| Failure consequence | Severe | Usually manageable |

HSSETips.com principle:

SIS must never be combined with normal control functions.

SIS Lifecycle (IEC 61508 / IEC 61511)

SIS must be managed across its entire lifecycle, including:

- Hazard and risk assessment (HAZOP, LOPA)

- SIL determination

- SIS design and engineering

- Installation and commissioning

- Validation and testing

- Operation and maintenance

- Proof testing and calibration

- Management of Change (MOC)

- Decommissioning

Skipping lifecycle steps is a common root cause of SIS failure.

SIS in Oil & Gas and Offshore FPSOs

Typical SIS applications include:

- High-pressure shutdown on separators

- Emergency shutdown of hydrocarbon flow

- Fire and gas integration

- Compressor anti-surge protection

- Boiler and burner management systems

On FPSOs, SIS is essential due to:

- Confined spaces

- High hydrocarbon inventory

- Limited evacuation options

Proof Testing and Maintenance of SIS

SIS reliability depends on:

- Regular proof testing

- Calibration of sensors

- Functional testing of final elements

HSSE Insight

A safety system that is not tested is not a safety system.

Poor proof testing is one of the leading contributors to hidden SIS failures.

Common SIS Failures and HSSE Lessons

❌ Using non-certified instruments

❌ Combining SIS and control systems

❌ Inadequate proof testing

❌ Poor documentation

❌ Unauthorized bypassing

Many major accidents involved disabled, bypassed, or degraded SIS.

SIS and Other Process Safety Barriers

SIS works alongside:

- Pressure relief devices (PSVs, rupture discs)

- Alarms and operator response

- Physical containment

- Permit to Work (PTW) systems

HSSE principle:

SIS is a critical barrier—but it is never the only barrier.

Roles and Responsibilities in SIS Management

Management

- Provide resources and oversight

- Ensure regulatory compliance

Engineers

- Design and maintain SIS integrity

- Ensure SIL requirements are met

HSSE Professionals

- Verify lifecycle compliance

- Audit SIS performance

- Monitor bypasses and overrides

Operators

- Understand SIS actions

- Report abnormal behavior

Applicable SIS Standards and Guidance

- IEC 61508 – Functional safety (general)

- IEC 61511 – SIS for process industry

- API RP 14C – Offshore safety systems

- ISO 10418 – Offshore production safety

- ISA TR84

Conclusion

Safety Instrumented Systems are not optional add-ons—they are life-saving systems designed to prevent major industrial disasters.

For HSSE professionals, understanding SIS is essential to:

- Prevent catastrophic incidents

- Ensure regulatory compliance

- Protect people, assets, and the environment

A well-designed SIS saves lives. A poorly managed SIS creates false confidence.

Frequently Asked Questions (FAQs)

Is SIS the same as an emergency shutdown system?

ESD is often part of the SIS, but SIS can include multiple safety functions.

Can alarms replace SIS?

No. Alarms depend on human response; SIS acts automatically.

Are pressure gauges allowed in SIS?

No. SIS requires certified sensors such as pressure transmitters.

How often should SIS be tested?

Based on SIL verification—commonly annually or per risk assessment.

Related Topics:

- 👉 How to Select Pressure Instruments for Safety-Critical Systems

- 👉 Pressure Transmitter Calibration and Uncertainty

- 👉 Pressure Equipment Safety Regulations

- 👉 Permit to Work (PTW) Systems Explained

- 👉Layers of Protection Analysis (LOPA) for FPSO Systems

- 👉FPSO Hazard & Operability Studies (HAZOP)

Pingback: Overpressure Protection Systems Explained: A Practical HSSE Guide to Preventing Catastrophic Pressure Failures - HSSE Tips