In high-hazard industries—oil and gas, FPSO operations, chemicals, power generation, and manufacturing—process safety failures rarely occur without warning. Instead, they are preceded by weak signals: abnormal trends, recurring alarms, near misses, and small deviations from procedures. When these signals are ignored, downplayed, or postponed, organizations fall victim to what is known as the ostrich effect.

In HSSE and process safety management, the ostrich effect represents a critical human and organizational vulnerability—one that can quietly undermine barriers and escalate minor issues into catastrophic events.

What Is the Ostrich Effect?

The ostrich effect is a cognitive bias where individuals or organizations avoid acknowledging negative, uncomfortable, or threatening information, especially when action may be costly, disruptive, or personally risky.

In process safety, it manifests as:

- Ignoring early warning signs of failure

- Delaying corrective actions despite evidence of risk

- Normalizing abnormal conditions

- Preferring short-term operational comfort over long-term safety integrity

In simple terms: “If we don’t look at the risk, we don’t have to deal with it.”

Why the Ostrich Effect Is Especially Dangerous in Process Safety

Process safety is fundamentally about controlling low-frequency, high-consequence events. These events are rarely sudden; they develop through creeping degradation of systems, barriers, and human performance.

When the ostrich effect takes hold:

- Early detection fails

- Barriers degrade silently

- Operational drift accelerates

- Major accident potential increases

Unlike personal safety incidents, process safety incidents affect entire facilities, with consequences including:

- Loss of containment

- Fires and explosions

- Toxic releases

- Environmental damage

- Fatalities and asset loss

Common Process Safety Examples of the Ostrich Effect

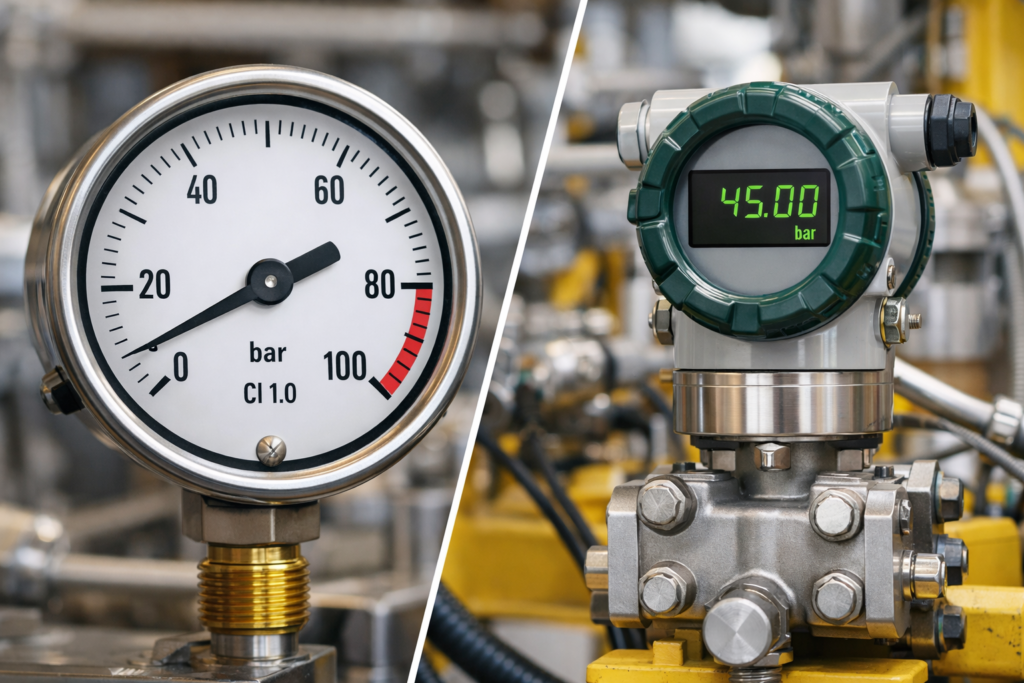

1. Alarm Fatigue and Alarm Ignoring

- Recurrent alarms accepted as “normal”

- Operators acknowledge alarms without investigation

- Alarm rationalization not prioritized

Result: Real emergencies are masked by noise.

2. Normalization of Deviance

- Equipment operating outside design limits becomes routine

- Temporary overrides become permanent

- Deviations are justified by past success

Result: Abnormal becomes normal—until it fails.

3. Deferred Maintenance and Integrity Issues

- Known corrosion or vibration trends postponed

- Inspection findings closed without effective repair

- Maintenance backlog accepted as business as usual

Result: Mechanical integrity barriers erode.

4. Underreporting of Near Misses

- Minor releases or upsets not reported

- Fear of blame, paperwork, or shutdown

- “Nothing happened, so why report?”

Result: Learning opportunities are lost.

5. Weak Management of Change (MOC)

- Changes treated as operational tweaks

- Risk assessments copied from previous cases

- Temporary changes never reviewed

Result: New hazards introduced unnoticed.

Human and Organizational Drivers Behind the Ostrich Effect

Psychological Factors

- Optimism bias (“It won’t happen to us”)

- Confirmation bias (seeing only reassuring data)

- Cognitive overload and decision fatigue

Organizational Factors

- Production pressure and KPIs outweighing safety

- Poor safety culture where bad news is punished

- Leadership detachment from frontline realities

Systemic Factors

- Ineffective alarm management

- Lack of meaningful leading indicators

- Weak assurance and independent challenge

The Ostrich Effect and Major Accident History

Many major industrial disasters share a common pattern:

- Warning signs existed

- Concerns were raised

- Signals were ignored or minimized

The ostrich effect does not cause accidents alone—but it allows multiple failures to align.

Recognizing the Early Warning Signs

Organizations should treat the following as red flags:

- “We’ve always done it this way”

- “It’s only temporary”

- “The alarm usually clears itself”

- “Fix it at the next shutdown”

- “Reporting will just create trouble”

These statements indicate avoidance behavior, not risk control.

How to Prevent the Ostrich Effect in Process Safety

1. Strengthen Alarm and Information Management

- Rationalize alarms so every alarm requires action

- Highlight trends, deviations, and rate of change

- Eliminate nuisance alarms

2. Embed Strong Process Safety Leadership

- Leaders must actively seek bad news

- Visible follow-up on safety concerns

- Reward early reporting—not silence

3. Improve Barrier Management

- Identify Safety-Critical Elements (SCEs)

- Monitor barrier health, not just outcomes

- Act on degradation signals early

4. Normalize Reporting, Not Deviance

- Encourage near-miss reporting

- Remove blame from honest mistakes

- Close feedback loops with visible actions

5. Build Human Factors Awareness

- Train teams on cognitive bias and decision traps

- Use scenario-based drills

- Include human factors in incident investigations

6. Reinforce Management of Change Discipline

- Treat all changes as potential risk creators

- Reassess “temporary” changes regularly

- Ensure technical authority review

Practical Process Safety Rule

If a process deviation feels uncomfortable, it deserves attention—regardless of past success.

Relevant Resources for Process Safety Professionals

To strengthen understanding and counter cognitive and organizational failures in process safety, the following resources are highly valuable:

- Process Safety Management Guidelines – Comprehensive references for hazard identification, barrier management, and risk control

👉 Check current editions on Amazon - Human Factors in Process Safety – Practical insight into cognitive bias, alarm handling, and operator decision-making

👉 View recommended titles on Amazon - Alarm Management Best Practices – Guides aligned with EEMUA-191 and ISA-18.2 principles

👉 Explore available books on Amazon

(Product availability and pricing may vary. Always review current specifications before purchase.)

Key Takeaway

The ostrich effect is not a lack of knowledge—it is a failure to act on what is already known. In process safety, ignored risks do not disappear; they accumulate silently until barriers fail.

A strong process safety system actively surfaces uncomfortable information, challenges assumptions, and treats weak signals as opportunities to prevent catastrophe—not inconveniences to be avoided.

Related Topics & Downloads:

- Operational Drift: The Hidden Safety Risk Undermining FPSO Operations and Tool Safety

- FPSO Process Safety Incident Case Studies and Lessons Learned: Preventing Major Offshore Accidents

- Inherent Safety in FPSO Design and Retrofit Projects: Reducing Risk at the Source

- FPSO Process Safety Incident Case Studies and Lessons Learned: Preventing Major Offshore Accidents

- HSSE Toolbox Talk On Slips, Trips, and Falls Prevention