Floating Production, Storage and Offloading units (FPSOs) operate with large inventories of hydrocarbons in a complex offshore environment where failures can escalate rapidly into major accident events (MAEs). To prevent and mitigate such events, FPSO operators rely on specific systems, equipment, and procedures that are essential to safety.

These are known as Safety Critical Elements (SCEs).

Effective identification, definition, and assurance of SCEs form the backbone of FPSO process safety, barrier management, and Safety Case compliance. When SCEs fail, the consequences are often severe.

This article provides a practical, FPSO-specific guide to Safety Critical Elements, explaining what they are, how they are identified, how performance standards are defined, and how ongoing assurance is achieved offshore.

What Are Safety Critical Elements (SCEs)?

Safety Critical Elements (SCEs) are systems, equipment, or procedures whose failure could:

- Cause a major accident, or

- Fail to prevent or mitigate the consequences of a major accident

In simple terms, if an element must work to keep people, the environment, or the asset safe during a major hazard scenario, it is safety-critical.

SCEs are central to:

- Major Accident Hazard (MAH) control

- Barrier management systems

- Safety Case demonstrations

- Regulatory inspections and audits

Why SCEs Are Critical on FPSOs

FPSOs face unique operational challenges that make SCE management especially important:

- High-pressure, high-temperature hydrocarbon processing

- Large crude oil storage volumes

- Congested topsides with limited escape routes

- Continuous operations and SIMOPS

- Offshore emergency response limitations

On FPSOs, there is little margin for failure. SCEs provide the last and most reliable lines of defense against catastrophic outcomes.

Relationship Between SCEs and Major Accident Hazards (MAHs)

Safety Critical Elements are identified based on Major Accident Hazards, such as:

- Loss of containment of hydrocarbons

- Fire and explosion

- Overpressure of vessels

- Gas release in confined spaces

- Offloading or turret system failures

Each MAH is controlled by preventive and mitigative barriers, and many of these barriers are SCEs.

SCEs are therefore not arbitrary lists of equipment — they are directly linked to credible accident scenarios.

How Safety Critical Elements Are Identified on FPSOs

SCE identification is typically based on structured risk studies, including:

1. HAZOP Studies

HAZOPs identify hazardous deviations and potential consequences.

2. Layers of Protection Analysis (LOPA)

LOPA evaluates which protection layers are required to reduce risk to tolerable levels.

3. Bow-Tie Risk Analysis

Bow-Tie diagrams visually link:

- Threats

- Preventive barriers

- Mitigative barriers

- Consequences

Any barrier that is essential to MAH control becomes a candidate SCE.

Types of Safety Critical Elements on FPSOs

1. Process Safety SCEs

Examples include:

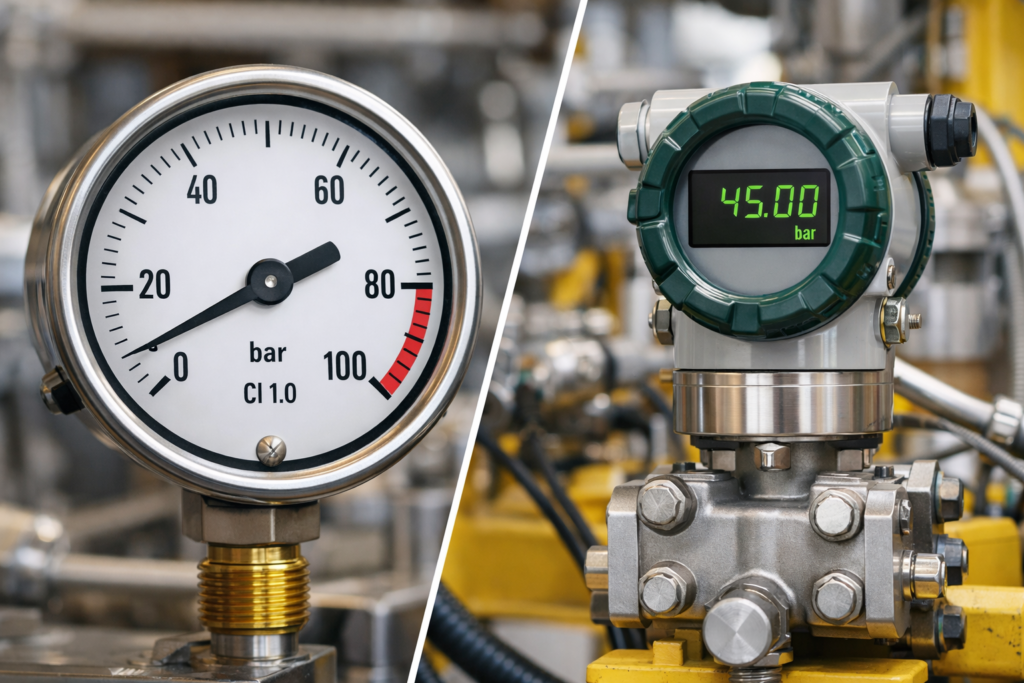

- Pressure Relief Valves (PRVs)

- Safety Instrumented Functions (SIFs)

- Emergency Shutdown (ESD) systems

- High-integrity pressure protection systems

- Fire and gas detection systems

These elements prevent or limit loss of containment and escalation.

2. Structural and Marine SCEs

Examples include:

- Hull and structural integrity systems

- Mooring and turret systems

- Offloading hoses and emergency release systems

- Collision protection measures

Failure of these elements can lead directly to major accidents.

3. Fire and Explosion Protection SCEs

Examples include:

- Passive fire protection

- Deluge and firefighting systems

- Fire pumps and hydrants

- Blast walls and firewalls

These SCEs reduce the consequences of fires and explosions.

4. Escape, Evacuation, and Rescue (EER) SCEs

Examples include:

- Temporary refuge

- Muster and alarm systems

- Lifeboats and launching systems

- Emergency lighting and signage

EER SCEs are critical for life-saving during escalation.

5. Procedural and Human SCEs

Not all SCEs are physical equipment.

Examples include:

- Emergency response procedures

- Permit to Work (PTW) systems

- SIMOPS controls

- Competency and training requirements

These procedural elements are often overlooked but equally critical.

Performance Standards for Safety Critical Elements

Every SCE must have a Performance Standard that defines how it should function.

A good performance standard includes:

1. Function

What the SCE is required to do

Example: Relieve excess pressure to prevent vessel rupture

2. Availability

When it must work

Example: Available at all times during operations

3. Reliability

How reliably it must perform

Example: Probability of failure on demand ≤ specified limit

4. Survivability

Ability to function during an accident

Example: Operable during fire or explosion

5. Interactions

Dependencies with other systems

Example: Power, air, control logic

SCE Assurance on FPSOs

Identifying SCEs is only the first step. Ongoing assurance is essential.

Key Assurance Activities Include:

- Inspection and testing regimes

- Preventive maintenance

- Functional testing

- Alarm and trip testing

- Audit and verification

- Competency assurance

- Management of Change (MOC)

Failure to assure SCE performance introduces hidden risk.

SCEs and Barrier Management

SCEs form the backbone of barrier management systems.

Each SCE should be:

- Clearly linked to a barrier

- Assigned ownership

- Monitored through KPIs

- Included in dashboards and audits

Effective barrier management ensures that SCEs remain healthy, visible, and reliable throughout the FPSO lifecycle.

Common SCE Management Pitfalls on FPSOs

- Poorly defined performance standards

- Treating SCEs as static lists

- Inadequate testing or inspection

- Over-reliance on alarms

- Weak management of change

- Lack of operations involvement

- Poor documentation and traceability

Best Practices for Managing SCEs on FPSOs

- Align SCEs directly with MAHs

- Use Bow-Tie diagrams to maintain clarity

- Digitize SCE registers and assurance tracking

- Integrate SCEs with maintenance systems

- Regularly review SCEs after changes or incidents

- Train offshore personnel on SCE awareness

- Assign clear ownership and accountability

Regulatory and Safety Case Expectations

Regulators expect FPSO operators to demonstrate that:

- MAHs are clearly identified

- SCEs are defined and justified

- Performance standards are appropriate

- Assurance activities are effective

- Risks are reduced to ALARP

SCEs are therefore central to Safety Case compliance and offshore regulatory confidence.

Conclusion

Safety Critical Elements are the cornerstone of FPSO process safety and major accident prevention. They represent the systems, equipment, and procedures that must work — without failure — to protect lives, the environment, and the asset.

When SCEs are clearly identified, properly specified, and rigorously assured, FPSO operators can confidently demonstrate effective control of major accident hazards and maintain safe offshore operations.

Related Articles & Further Reading

To strengthen your understanding of FPSO process safety and barrier management, explore these related guides:

- FPSO Hazard & Operability Studies (HAZOP): Step-by-Step Guide

- Layers of Protection Analysis (LOPA) for FPSO Systems

- Bow-Tie Risk Analysis for FPSO Major Accident Hazards

- Process Safety and Barrier Management on FPSOs

- Safety Instrumented Systems (SIS) Explained

- Overpressure Protection Systems Explained