Floating Production, Storage and Offloading units (FPSOs) operate with high hydrocarbon inventories, complex process systems, and multiple interfaces between production, marine, and offloading activities. While qualitative risk assessment tools such as HAZOP are effective for identifying hazards, they often stop short of answering a critical question:

Is the level of risk acceptable?

This is where Layers of Protection Analysis (LOPA) becomes essential. LOPA provides a structured, semi-quantitative method to evaluate whether existing safeguards on FPSO systems are sufficient to prevent major accident events (MAEs).

This article explains LOPA for FPSO systems, how it works, when it is used, and how it integrates with HAZOP, Safety Instrumented Systems (SIS), and barrier management offshore.

What Is Layers of Protection Analysis (LOPA)?

Layers of Protection Analysis (LOPA) is a risk assessment technique used to evaluate the adequacy of Independent Protection Layers (IPLs) that prevent or mitigate hazardous events.

LOPA sits between:

- Qualitative methods (e.g. HAZOP)

- Fully quantitative methods (e.g. QRA)

It estimates risk by combining:

- Frequency of initiating events

- Probability of failure of protection layers

- Consequence severity

The outcome helps determine whether additional safeguards are required to reduce risk to tolerable levels.

Why LOPA Is Critical for FPSO Operations

FPSOs present unique risk challenges that make LOPA particularly valuable:

- Large inventories of hydrocarbons in compact topsides

- Continuous processing and storage

- High-pressure separation and compression systems

- Marine and offloading interfaces

- SIMOPS and human interaction

- Limited evacuation and escape options offshore

On FPSOs, multiple layers of protection must work reliably and independently. LOPA provides a defensible method to test this assumption.

When Is LOPA Used on FPSOs?

LOPA is typically applied:

1. After a HAZOP Study

- To evaluate high-risk HAZOP scenarios

- When consequences are severe (fire, explosion, loss of containment)

2. During SIS Design or Modification

- To determine required Safety Integrity Levels (SIL)

- To justify SIF performance requirements

3. For Brownfield Modifications

- When changes impact existing safeguards

- As part of Management of Change (MOC)

4. During Process Safety Revalidation

- To confirm risk remains ALARP over time

Key Concepts in FPSO LOPA Studies

Initiating Event

An initiating event is the starting cause of a hazardous scenario, such as:

- Control valve failure

- Blocked outlet

- Instrument malfunction

- Operator error

- Power failure

Each initiating event is assigned a credible frequency.

Independent Protection Layers (IPLs)

An IPL is a safeguard that:

- Prevents or mitigates a hazardous event

- Is independent of other layers

- Is auditable and reliable

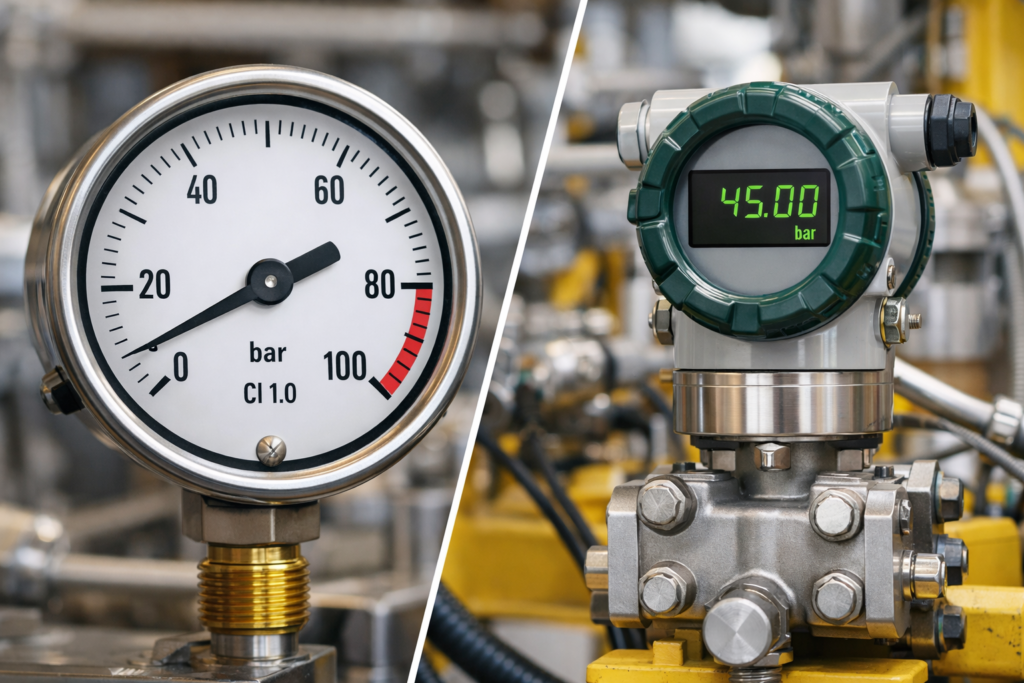

Typical FPSO IPLs include:

- Basic Process Control System (BPCS)

- Alarms with operator response

- Safety Instrumented Functions (SIFs)

- Pressure Relief Valves (PRVs)

- Emergency Shutdown (ESD) systems

- Physical barriers and containment

Consequences

Consequences are evaluated based on:

- Personnel safety (fatalities, injuries)

- Asset damage

- Environmental impact

- Production loss

FPSO consequences are often high severity due to offshore constraints.

Step-by-Step LOPA Process for FPSO Systems

Step 1: Select Scenarios from HAZOP

Not all HAZOP deviations require LOPA. LOPA is applied to:

- High-severity scenarios

- Scenarios with limited safeguards

- Scenarios requiring SIL determination

Example FPSO Scenario:

High pressure in first-stage separator leading to vessel rupture.

Step 2: Define the Initiating Event Frequency

Initiating event frequencies are typically based on:

- Industry databases

- Historical FPSO data

- Engineering judgement

Example:

Control valve failure frequency = 1 × 10⁻¹ per year

Step 3: Identify Credible IPLs

Each IPL must be:

- Independent

- Effective

- Designed to prevent the consequence

Example IPLs for FPSO Separator Overpressure:

- High-pressure alarm + operator response

- High-high pressure SIF

- Pressure relief valve to flare

Step 4: Assign Probability of Failure on Demand (PFD)

Each IPL is assigned a PFD value based on:

- Design

- Testing frequency

- Human reliability (if applicable)

Typical PFD values:

- Alarm with operator action: ~0.1

- SIF (SIL 1): ~0.1

- SIF (SIL 2): ~0.01

- PRV: ~0.01

Step 5: Calculate Mitigated Event Frequency

The initiating event frequency is multiplied by the PFDs of all IPLs.

Example:

Initiating event: 1 × 10⁻¹ / year

Alarm PFD: 0.1

SIF PFD: 0.01

Mitigated frequency =

1 × 10⁻¹ × 0.1 × 0.01 = 1 × 10⁻⁴ per year

Step 6: Compare Against Risk Tolerance Criteria

The calculated frequency is compared against:

- Corporate risk criteria

- Regulatory expectations

- ALARP principles

If risk is not tolerable, additional IPLs or improved reliability is required.

Step 7: Identify Risk Reduction Measures

If gaps exist, recommendations may include:

- Adding a new SIF

- Increasing SIL rating

- Improving alarm management

- Enhancing operator training

- Design modifications

Relationship Between LOPA and SIS on FPSOs

LOPA is a key input to SIL determination for Safety Instrumented Functions.

- LOPA defines the required risk reduction

- Risk reduction determines SIL level

- SIL level drives SIS design, testing, and maintenance

Without LOPA, SIS design lacks a defensible risk basis.

Common FPSO LOPA Pitfalls

- Treating alarms as independent IPLs when they are not

- Overestimating operator response reliability

- Double-counting safeguards

- Ignoring human factors

- Poor documentation of assumptions

- Not updating LOPA after modifications

Best Practices for FPSO LOPA Studies

- Use experienced facilitators with offshore knowledge

- Integrate LOPA closely with HAZOP workshops

- Clearly define IPL independence

- Align with barrier management frameworks

- Digitally track LOPA recommendations

- Revalidate LOPA during lifecycle changes

LOPA vs Other Risk Assessment Tools

| Tool | Purpose |

|---|---|

| HAZOP | Hazard identification |

| LOPA | Risk adequacy assessment |

| Bow-Tie | Barrier visualization |

| QRA | Quantitative risk modeling |

| FMEA | Equipment failure analysis |

LOPA bridges the gap between identification and quantification.

Conclusion

Layers of Protection Analysis (LOPA) is a powerful and practical tool for evaluating process safety risks on FPSOs. By systematically assessing initiating events, safeguards, and risk tolerability, LOPA ensures that offshore process systems are protected by adequate, independent, and reliable layers of defense.

For FPSO operators and HSSE professionals, effective LOPA implementation strengthens compliance, improves decision-making, and most importantly, prevents major accidents offshore.

Frequently Asked Questions (FAQs)

How does LOPA differ from HAZOP?

HAZOP identifies hazards, while LOPA evaluates whether safeguards reduce risk to acceptable levels.

Is LOPA mandatory for FPSOs?

LOPA is often required by company standards and regulators, especially for SIL determination.

How often should LOPA be updated?

Whenever significant process changes occur and during periodic safety revalidation.