Floating Production, Storage and Offloading units (FPSOs) operate with large hydrocarbon inventories in confined offshore environments. Traditionally, offshore safety has relied heavily on engineered safeguards, procedures, and emergency response systems to control risk.

However, the most effective way to manage risk is not to control hazards — but to eliminate or reduce them at the source.

This is the core philosophy of Inherent Safety.

Inherent safety focuses on designing FPSO systems and layouts in a way that removes hazards altogether or significantly reduces their severity, rather than relying solely on protective layers. This approach is increasingly important for both new-build FPSOs and retrofit or brownfield modification projects.

This article explains what inherent safety is, why it matters on FPSOs, and how it can be practically applied during design and retrofit projects.

What Is Inherent Safety?

Inherent Safety is a process safety philosophy that aims to prevent accidents by eliminating or minimizing hazards, rather than managing them with additional controls.

Unlike add-on safeguards such as alarms, trips, or procedures, inherent safety measures are built into the design and do not rely on human intervention or system activation.

Inherent safety is commonly summarized by four key principles:

- Minimize

- Substitute

- Moderate

- Simplify

Why Inherent Safety Is Critical for FPSOs

FPSOs present unique challenges that make inherent safety especially valuable:

- Large volumes of flammable hydrocarbons

- Congested topsides with limited separation distances

- Continuous operations with SIMOPS

- Limited escape and evacuation options

- Aging assets and brownfield modifications

- Increasing complexity of process systems

On an FPSO, every additional safeguard introduces complexity, while inherent safety reduces dependence on barriers that can fail.

The Four Principles of Inherent Safety Applied to FPSOs

1. Minimize – Reduce Hazard Inventory

Principle:

Use the smallest possible quantity of hazardous material.

FPSO Examples:

- Reducing process hold-up volumes

- Minimizing hydrocarbon inventory in separators

- Limiting intermediate storage where feasible

- Reducing pipeline and vessel volumes during redesign

Smaller inventories reduce the consequences of loss of containment events.

2. Substitute – Use Less Hazardous Materials or Processes

Principle:

Replace hazardous materials or processes with safer alternatives.

FPSO Examples:

- Using low-toxicity chemicals instead of hazardous ones

- Replacing flammable hydraulic fluids with fire-resistant fluids

- Substituting diesel-driven equipment with electric systems

- Using inert gas systems to reduce flammability risk

Substitution directly lowers the severity of potential accidents.

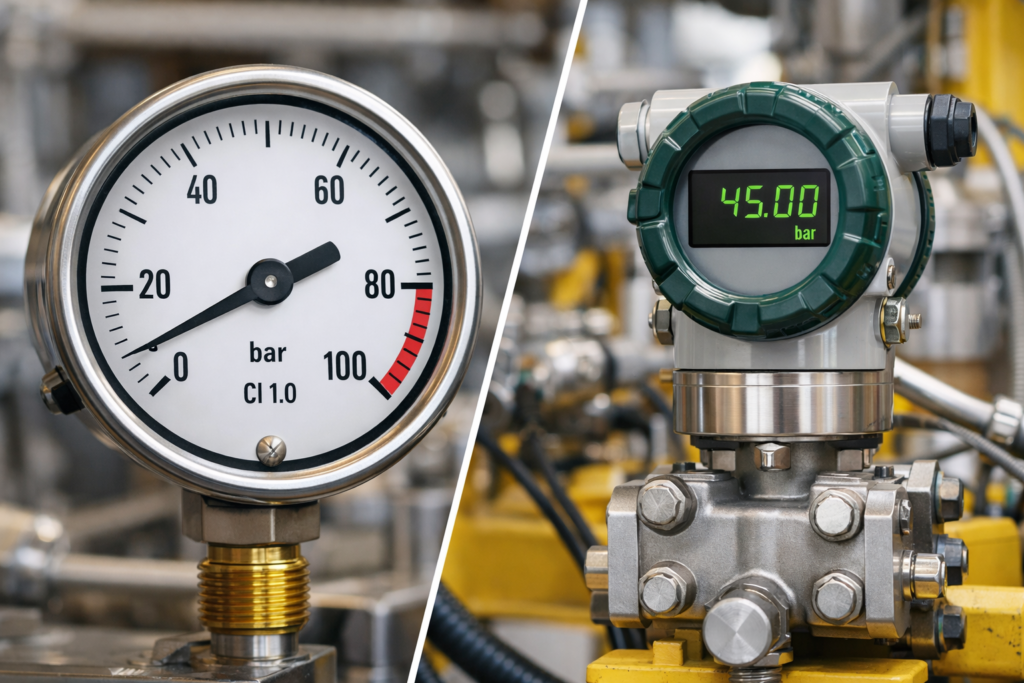

3. Moderate – Reduce Severity of Conditions

Principle:

Operate at less extreme conditions where possible.

FPSO Examples:

- Lower operating pressures and temperatures

- Using dilution or inerting to reduce flammable atmospheres

- Operating below critical limits where design allows

- Locating high-risk equipment away from manned areas

Moderation reduces both likelihood and consequence of failure.

4. Simplify – Eliminate Complexity and Error Traps

Principle:

Design systems that are simpler, more intuitive, and less error-prone.

FPSO Examples:

- Reducing unnecessary valves and bypasses

- Simplifying process flow paths

- Standardizing equipment and controls

- Improving layout clarity and accessibility

- Designing systems that fail safely

Simpler systems are easier to operate, maintain, and recover during abnormal situations.

Inherent Safety in FPSO New-Build Design

The greatest opportunity for inherent safety exists during early project phases:

- Concept selection

- FEED (Front End Engineering Design)

- Detailed engineering

Key Design Opportunities Include:

- Optimized topsides layout and segregation

- Early inventory minimization

- Separation of hazardous and non-hazardous areas

- Early consideration of escape, evacuation, and rescue (EER)

- Reduced reliance on complex active safety systems

Early design decisions can eliminate risks that would otherwise require lifelong management.

Inherent Safety in FPSO Retrofit and Brownfield Projects

While retrofits offer fewer degrees of freedom than new builds, significant inherent safety improvements are still possible.

Practical Retrofit Examples:

- Removing redundant equipment

- Eliminating dead legs and trapped volumes

- Re-routing piping to reduce congestion

- Upgrading to safer chemicals or utilities

- Simplifying control logic

- Reducing manual intervention requirements

Even small inherent safety improvements can deliver disproportionate risk reduction.

Relationship Between Inherent Safety and HAZOP

HAZOP studies often identify deviations that are later controlled by alarms, trips, or procedures. Inherent safety challenges teams to ask:

“Can this hazard be removed or reduced instead of controlled?”

Inherent safety reviews are most effective when conducted:

- Before or alongside HAZOP

- During concept selection

- During major modifications

HAZOP findings can often be addressed more robustly through design changes rather than additional safeguards.

Inherent Safety, LOPA, and Bow-Tie Analysis

Inherent safety influences risk assessment outcomes directly:

- LOPA: Lower initiating event frequency and consequence severity

- Bow-Tie: Fewer threats and simpler barrier structures

- Barrier Management: Reduced dependence on active barriers

When hazards are inherently reduced, fewer layers of protection are required.

Inherent Safety and Safety Critical Elements (SCEs)

Effective inherent safety reduces:

- The number of Safety Critical Elements

- The performance demands on remaining SCEs

- The likelihood of SCE failure during an accident

This improves long-term operability, maintenance, and assurance on FPSOs.

Common Barriers to Inherent Safety on FPSOs

- Late consideration in project lifecycle

- Production-driven design compromises

- Space and weight constraints

- Brownfield integration challenges

- Cost-focused decision-making

- Misconception that inherent safety is “too expensive”

In reality, inherent safety often reduces lifecycle cost by simplifying systems and reducing maintenance.

Best Practices for Implementing Inherent Safety on FPSOs

- Apply inherent safety thinking early

- Include inherent safety reviews in design gates

- Challenge every new safeguard: Can we remove the hazard instead?

- Involve operations and maintenance teams

- Use inherent safety checklists during modifications

- Document inherent safety decisions in Safety Case updates

- Combine inherent safety with barrier management

Regulatory and Industry Expectations

Regulators increasingly expect FPSO operators to:

- Demonstrate hazard elimination where practicable

- Justify reliance on safeguards

- Show ALARP through design choices

- Consider inherent safety during modifications

Inherent safety strengthens Safety Case credibility and regulatory confidence.

Conclusion

Inherent safety represents the strongest and most reliable form of risk control for FPSOs. By eliminating hazards or reducing their severity at the design stage, FPSO operators can significantly lower the likelihood and impact of major accidents.

Whether applied during new-build projects or retrofit modifications, inherent safety reduces reliance on complex systems, human intervention, and emergency response — resulting in safer, simpler, and more resilient offshore operations.

Related Articles & Further Reading

To deepen your understanding of FPSO process safety and risk management, explore these related guides:

- FPSO Hazard & Operability Studies (HAZOP): Step-by-Step Guide

- Layers of Protection Analysis (LOPA) for FPSO Systems

- Bow-Tie Risk Analysis for FPSO Major Accident Hazards

- Safety Critical Elements (SCEs) on FPSOs

- FPSO Risk Assessment Techniques Beyond HAZOP