Hazard and Operability Studies (HAZOP) are a cornerstone of process safety in offshore oil and gas operations. On Floating Production, Storage and Offloading units (FPSOs), HAZOP plays a critical role in identifying hazardous deviations and operability issues.

However, HAZOP alone is not sufficient to fully understand and manage the complex risk landscape of FPSOs.

FPSOs operate with large hydrocarbon inventories, congested topsides, marine and offloading interfaces, and continuous operations. To effectively control major accident hazards (MAHs) and demonstrate that risks are As Low As Reasonably Practicable (ALARP), operators must apply additional, complementary risk assessment techniques.

This article explores the key risk assessment techniques used on FPSOs beyond HAZOP, explaining when they are applied, what they deliver, and how they work together within an integrated process safety framework.

Why FPSOs Need Risk Assessment Beyond HAZOP

HAZOP is highly effective at answering the question:

“What can go wrong?”

But FPSO operators also need answers to:

- How likely is the event?

- Are existing safeguards sufficient?

- Which barriers are safety-critical?

- What happens if multiple barriers fail?

- How do human actions affect risk?

- Are risks tolerable or ALARP?

These questions require additional analytical tools beyond traditional HAZOP workshops.

Overview of FPSO Risk Assessment Techniques

Common risk assessment techniques used on FPSOs include:

- Layers of Protection Analysis (LOPA)

- Bow-Tie Risk Analysis

- Failure Modes and Effects Analysis (FMEA / FMECA)

- Quantitative Risk Assessment (QRA)

- Human Reliability Analysis (HRA)

- Barrier Management and SCE analysis

Each technique serves a different purpose and addresses a specific aspect of risk.

1. Layers of Protection Analysis (LOPA)

Purpose:

To evaluate whether existing safeguards reduce risk to tolerable levels.

LOPA is a semi-quantitative method applied after HAZOP to assess high-severity scenarios. It evaluates:

- Initiating event frequency

- Independent Protection Layers (IPLs)

- Risk reduction effectiveness

FPSO Applications:

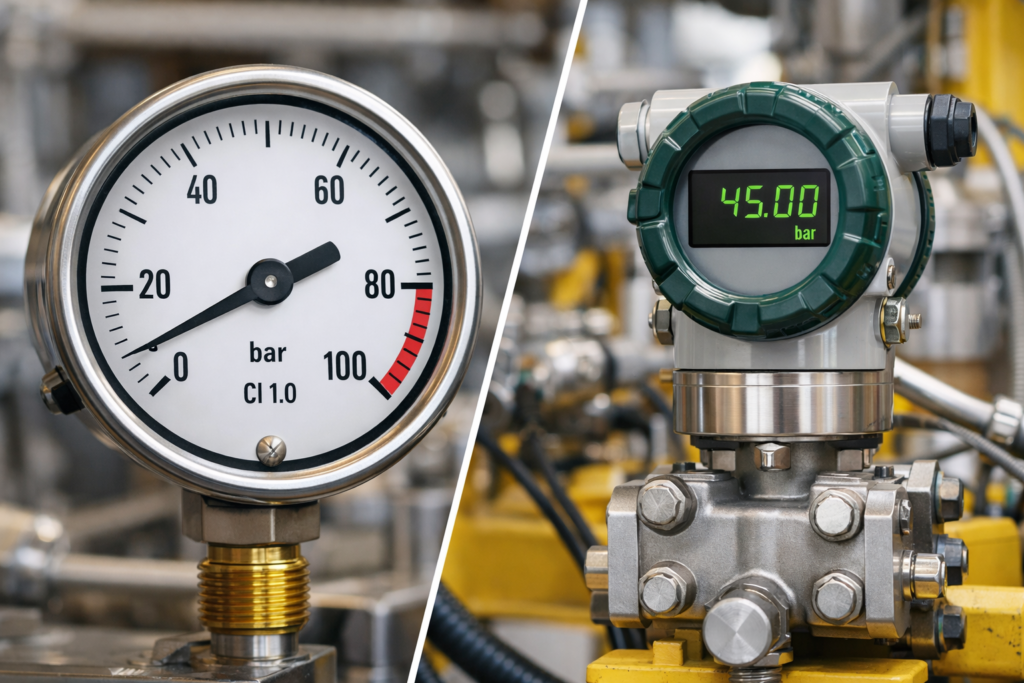

- Determining SIL requirements for Safety Instrumented Functions (SIFs)

- Evaluating overpressure scenarios

- Assessing adequacy of alarms, trips, and relief systems

LOPA bridges the gap between qualitative HAZOP and fully quantitative risk studies.

2. Bow-Tie Risk Analysis

Purpose:

To visually link hazards, threats, barriers, and consequences.

Bow-Tie analysis combines:

- Fault-tree thinking (causes)

- Event-tree thinking (consequences)

FPSO Applications:

- Major Accident Hazard (MAH) identification

- Barrier management and assurance

- Safety Case demonstrations

- Workforce safety awareness

Bow-Tie diagrams are especially effective offshore because they clearly show how risks are controlled in practice.

3. Failure Modes and Effects Analysis (FMEA / FMECA)

Purpose:

To analyze how individual equipment or system failures affect operations and safety.

FMEA is a bottom-up technique that examines:

- Failure modes

- Causes of failure

- Effects on the system

- Detection and mitigation

FPSO Applications:

- Critical rotating equipment

- Marine and turret systems

- Power generation and utilities

- Instrumentation and control components

When combined with criticality analysis (FMECA), it helps prioritize maintenance and inspection efforts.

4. Quantitative Risk Assessment (QRA)

Purpose:

To numerically estimate risk to people, assets, and the environment.

QRA uses mathematical models to quantify:

- Frequency of hazardous events

- Consequences (fire, explosion, toxic release)

- Individual and societal risk

FPSO Applications:

- Facility layout and design justification

- Temporary refuge and escape analysis

- Regulatory risk acceptance demonstrations

- Comparison of design options

QRA provides numerical risk values, but depends heavily on assumptions and data quality.

5. Human Reliability Analysis (HRA)

Purpose:

To assess the likelihood and impact of human error.

HRA evaluates:

- Safety-critical human actions

- Performance Shaping Factors (PSFs)

- Probability of human failure

FPSO Applications:

- Operator response to alarms

- Manual emergency shutdown actions

- Maintenance and isolation activities

- Emergency response and evacuation

HRA ensures that human actions credited as safeguards are realistic and defensible.

6. Barrier Management and Safety Critical Elements (SCEs)

Purpose:

To ensure that risk control barriers remain effective throughout the FPSO lifecycle.

Barrier management identifies:

- Preventive and mitigative barriers

- Safety Critical Elements (SCEs)

- Performance standards

- Assurance activities

FPSO Applications:

- Linking risk studies to maintenance systems

- Tracking barrier health through KPIs

- Demonstrating ongoing control of MAHs

Barrier management turns risk assessment outputs into day-to-day operational control.

How These Techniques Work Together on FPSOs

Effective FPSO risk management uses these tools in an integrated manner:

- HAZOP identifies hazards and deviations

- LOPA checks whether safeguards are sufficient

- Bow-Tie visualizes barriers and escalation

- FMEA assesses equipment reliability

- HRA evaluates human performance risk

- QRA quantifies overall risk

- Barrier Management ensures long-term effectiveness

No single technique is sufficient on its own.

Choosing the Right Risk Assessment Tool

| Situation | Recommended Technique |

|---|---|

| Hazard identification | HAZOP |

| Safeguard adequacy | LOPA |

| MAH visualization | Bow-Tie |

| Equipment reliability | FMEA / FMECA |

| Human error risk | HRA |

| Regulatory risk demonstration | QRA |

| Ongoing risk control | Barrier Management |

Selecting the right tool improves both safety and efficiency.

Common Pitfalls in FPSO Risk Assessment

- Over-reliance on HAZOP alone

- Treating studies as one-time exercises

- Poor integration between methods

- Weak follow-up and action tracking

- Over-crediting alarms or human actions

- Lack of operational involvement

Risk studies must remain living processes, not static reports.

Best Practices for FPSO Risk Assessment

- Use multiple, complementary techniques

- Align studies with Major Accident Hazards

- Involve operations, maintenance, and marine teams

- Integrate outputs into barrier management systems

- Regularly revalidate studies

- Use risk assessments to drive real decisions

- Focus on effectiveness, not paperwork

Regulatory and Safety Case Expectations

Regulators increasingly expect FPSO operators to demonstrate that:

- Risks are identified using appropriate tools

- Safeguards are justified and effective

- MAHs are controlled and monitored

- Human and cyber risks are considered

- Risk is reduced to ALARP

Using risk assessment techniques beyond HAZOP strengthens regulatory confidence and safety performance.

Conclusion

While HAZOP remains a foundational process safety tool, FPSO risk management requires more than HAZOP alone. Techniques such as LOPA, Bow-Tie analysis, FMEA, QRA, and HRA provide deeper insight into risk likelihood, consequence severity, and barrier effectiveness.

By applying these methods together and embedding them into barrier management systems, FPSO operators can achieve robust, defensible, and practical control of offshore risk.

Related Articles & Further Reading

To deepen your understanding of FPSO process safety and risk management, explore these related guides:

- FPSO Hazard & Operability Studies (HAZOP): Step-by-Step Guide

- Layers of Protection Analysis (LOPA) for FPSO Systems

- Bow-Tie Risk Analysis for FPSO Major Accident Hazards

- Safety Critical Elements (SCEs) on FPSOs

- Human Factors and Human Reliability Analysis (HRA) in FPSO Safety

- Managing Cyber-Physical Risk in Offshore Safety Systems