Floating Production, Storage and Offloading units (FPSOs) operate some of the most hazardous process systems in the offshore oil and gas industry. Despite robust engineering design, advanced control systems, and extensive procedures, process safety incidents still occur — often with severe consequences.

History has shown that major offshore accidents are rarely caused by a single failure. Instead, they result from a combination of technical, human, organizational, and management weaknesses that develop over time.

Studying process safety incident case studies is therefore one of the most powerful ways to improve FPSO safety performance. Each incident provides valuable lessons that help operators strengthen barriers, improve decision-making, and prevent recurrence.

This article reviews typical FPSO process safety incident scenarios, analyzes their root causes, and highlights practical lessons learned for safer offshore operations.

Why Incident Case Studies Matter in FPSO Process Safety

Incident investigations consistently show that:

- Warning signs existed before the event

- Barriers were degraded or bypassed

- Risks were underestimated or normalized

- Learning opportunities were missed

For FPSOs, where consequences can be catastrophic, learning from incidents is not optional — it is essential.

Case studies help to:

- Validate risk assessments

- Test the effectiveness of barriers

- Improve training and competence

- Strengthen Safety Case demonstrations

- Prevent repetition of past mistakes

Common Types of FPSO Process Safety Incidents

Process safety incidents on FPSOs typically fall into the following categories:

- Hydrocarbon loss of containment

- Overpressure and vessel failures

- Fire and explosion events

- Control and safety system failures

- Offloading and marine interface incidents

- Utility and power system failures

The following case study scenarios reflect realistic offshore events and the lessons derived from them.

Case Study 1: Hydrocarbon Release Due to Corrosion Failure

Incident Summary

An FPSO experienced a hydrocarbon gas release from process piping on the topsides. The release occurred during normal operations and resulted in gas detection alarms and an emergency shutdown. Fortunately, ignition did not occur.

Key Contributing Factors

- Undetected internal corrosion

- Inadequate inspection and monitoring

- Degraded pipework not identified as safety-critical

- Assumptions that corrosion rates were low

Lessons Learned

- Loss of containment often results from degraded mechanical integrity

- Corrosion circuits must be clearly defined and monitored

- Safety Critical Elements (SCEs) must include piping where failure could lead to MAHs

- Inspection programs must be risk-based and regularly reviewed

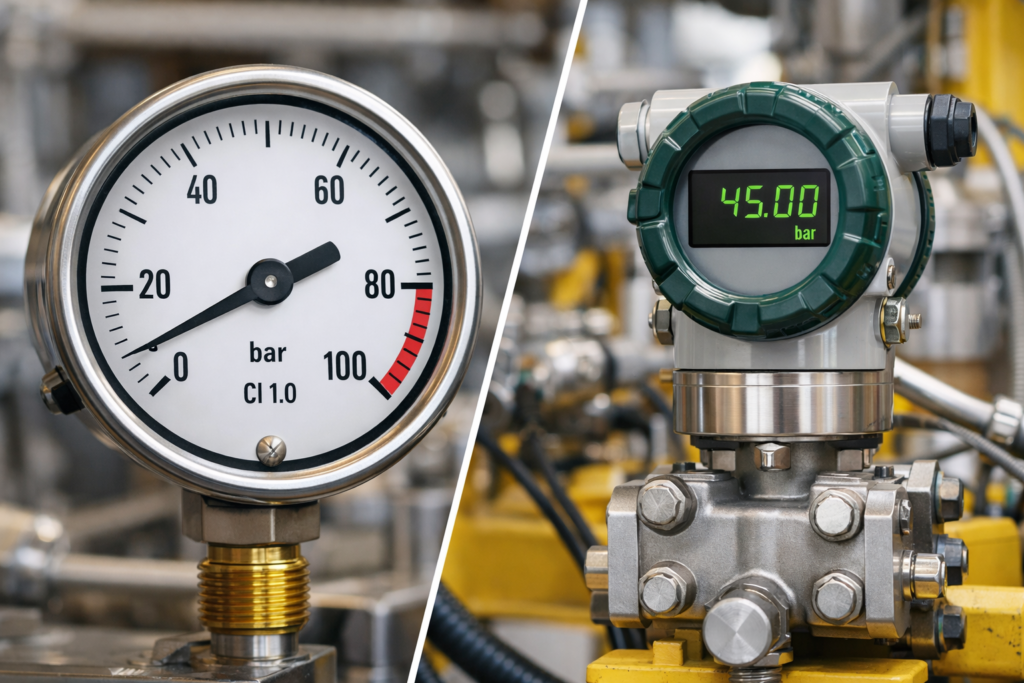

Case Study 2: Overpressure of Process Vessel During Startup

Incident Summary

During FPSO startup following maintenance, a process vessel was exposed to overpressure conditions due to a blocked outlet and control valve malfunction. Pressure relief devices activated, preventing vessel rupture.

Key Contributing Factors

- Incomplete line-up verification

- Inadequate startup procedures

- Operator unfamiliarity with abnormal conditions

- Over-reliance on automatic protection

Lessons Learned

- Startup and shutdown phases carry higher process safety risk

- Human factors play a critical role during non-routine operations

- Overpressure protection systems must be supported by clear procedures

- HAZOP and LOPA assumptions must be validated during operations

Case Study 3: Fire Following Loss of Containment on Topsides

Incident Summary

A hydrocarbon liquid leak occurred on FPSO topsides and ignited, resulting in a localized fire. Fire and gas detection activated, and deluge systems successfully controlled the fire.

Key Contributing Factors

- Flange leak due to improper tightening

- Inadequate torque control during maintenance

- Congested layout increasing escalation risk

Lessons Learned

- Maintenance quality is a critical process safety barrier

- Permit to Work (PTW) and isolation controls must be rigorous

- Layout and congestion significantly influence escalation potential

- Fire protection systems are mitigative — prevention remains the priority

Case Study 4: Control System Failure Leading to Unsafe Process Conditions

Incident Summary

A Distributed Control System (DCS) malfunction resulted in incorrect process readings being displayed in the control room. Operators unknowingly operated outside safe limits before the issue was identified.

Key Contributing Factors

- Instrument failure not detected by diagnostics

- Inadequate cross-checking of indications

- Alarm management weaknesses

- Limited operator awareness of system failure modes

Lessons Learned

- Control systems are not infallible

- Operators must be trained to recognize abnormal indications

- Alarm rationalization and system health monitoring are essential

- Safety Instrumented Systems (SIS) independence must be preserved

Case Study 5: Offloading Incident During Tandem Operations

Incident Summary

During tandem offloading, an FPSO experienced excessive hose movement due to unexpected vessel motion. Emergency release systems were activated, preventing a major spill.

Key Contributing Factors

- Inadequate weather window assessment

- Communication gaps between FPSO and shuttle tanker

- SIMOPS complexity

Lessons Learned

- Marine and offloading operations are major accident scenarios

- SIMOPS require robust coordination and authority

- Emergency systems must be tested and maintained

- Decision-making under commercial pressure must be challenged

Common Root Causes Across FPSO Incidents

Despite differing scenarios, recurring root causes include:

- Degraded barriers not detected in time

- Weak Management of Change (MOC)

- Human factors and fatigue

- Over-reliance on procedures or automation

- Poor learning from previous incidents

- Normalization of deviation

- Insufficient verification and assurance

Most major incidents are organizational failures as much as technical ones.

Integrating Lessons Learned Into FPSO Safety Management

To be effective, lessons learned must be:

- Documented and communicated

- Translated into actionable improvements

- Embedded into systems and training

- Verified for effectiveness

Practical integration methods include:

- Updating HAZOP, LOPA, and Bow-Tie analyses

- Revising SCE performance standards

- Enhancing barrier management dashboards

- Incorporating case studies into training

- Strengthening audits and assurance programs

Role of Process Safety Tools in Preventing Repeat Incidents

Incident learnings directly strengthen:

- HAZOP: Identifying previously overlooked deviations

- LOPA: Reassessing safeguard adequacy

- Bow-Tie: Revealing degraded barriers

- SCE Management: Improving assurance focus

- Human Factors: Reducing error traps

- Inherent Safety: Eliminating hazards where possible

Process safety tools are most effective when continuously informed by real-world events.

Regulatory and Industry Expectations

Regulators expect FPSO operators to:

- Investigate incidents thoroughly

- Share lessons learned internally

- Demonstrate improvements following incidents

- Prevent recurrence through system changes

- Use incident data to support ALARP arguments

Failure to learn from incidents is often viewed as a serious management failure.

Best Practices for Learning From FPSO Incidents

- Treat near misses with the same seriousness as incidents

- Focus on system weaknesses, not individual blame

- Involve offshore crews in learning reviews

- Track actions to closure and verify effectiveness

- Periodically review historical incidents

- Share lessons across assets and projects

A strong learning culture is a hallmark of high-reliability offshore operations.

Conclusion

FPSO process safety incident case studies provide invaluable insight into how and why offshore accidents occur. By analyzing real-world failures and understanding their underlying causes, operators can strengthen barriers, improve decision-making, and prevent recurrence.

For FPSOs, the cost of not learning from incidents is simply too high. Effective use of incident lessons transforms past failures into future safety improvements — protecting people, the environment, and critical offshore assets.

Related Articles & Further Reading

To further strengthen your FPSO process safety knowledge, explore these related guides:

- FPSO Hazard & Operability Studies (HAZOP): Step-by-Step Guide

- Layers of Protection Analysis (LOPA) for FPSO Systems

- Bow-Tie Risk Analysis for FPSO Major Accident Hazards

- Safety Critical Elements (SCEs) on FPSOs

- Inherent Safety in FPSO Design and Retrofit Projects