Floating Production, Storage and Offloading units (FPSOs) operate some of the most complex and high-hazard process systems in the offshore oil and gas industry. Large hydrocarbon inventories, confined topsides, marine interfaces, and simultaneous operations significantly elevate the risk of major accidents.

To systematically identify and control these risks, Hazard and Operability Studies (HAZOP) remain one of the most powerful and widely applied process safety risk assessment techniques on FPSOs.

This article provides a step-by-step, FPSO-specific guide to HAZOP studies, explaining how they are conducted, who should be involved, what to analyze, and how findings are managed to improve offshore process safety performance.

What Is a HAZOP Study?

A Hazard and Operability Study (HAZOP) is a structured, team-based risk assessment technique used to identify:

- Potential hazards

- Deviations from design intent

- Operability problems

- Consequences of failures

- Adequacy of existing safeguards

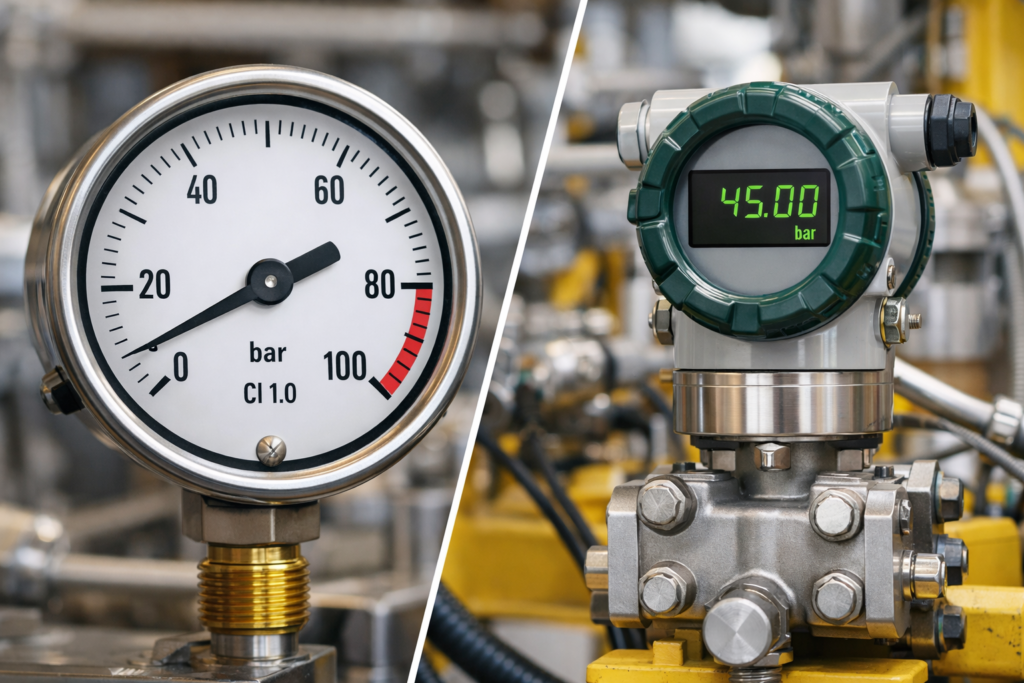

HAZOP uses guidewords (such as No, More, Less, Reverse) applied to process parameters (flow, pressure, temperature, level, composition) to challenge how a system might deviate from its intended operation.

Why HAZOP Is Critical for FPSO Operations

HAZOP is especially critical for FPSOs due to:

- High-pressure and high-temperature hydrocarbon processing

- Large crude oil storage volumes

- Complex offloading and turret systems

- Tight layout and congestion

- Simultaneous operations (SIMOPS)

- Continuous production with limited shutdown opportunities

On FPSOs, even small deviations can escalate rapidly into major accident events (MAEs) such as fires, explosions, or loss of containment.

When Are HAZOP Studies Performed on FPSOs?

HAZOPs are conducted at several stages across the FPSO lifecycle:

1. Design Phase

- Concept selection

- FEED (Front End Engineering Design)

- Detailed engineering

2. Modification and Upgrade Projects

- Process changes

- Capacity increases

- Tie-ins and brownfield modifications

3. Operational Revalidation

- Periodic HAZOP revalidation (typically every 5 years)

- Following major incidents or near misses

Step-by-Step FPSO HAZOP Study Process

Step 1: Define the Scope and Objectives

The first step is to clearly define:

- Systems to be reviewed (e.g. separation, compression, produced water)

- Boundaries of the study

- Interfaces with marine, utilities, and offloading systems

- Objectives (safety, operability, environmental protection)

A well-defined scope prevents gaps and unnecessary complexity.

Step 2: Assemble the HAZOP Team

HAZOP effectiveness depends on a multidisciplinary team, typically including:

- HAZOP facilitator (independent and trained)

- Process engineer

- Operations representative

- Maintenance or integrity engineer

- Instrumentation and control engineer

- HSSE specialist

- Marine or offloading representative (for FPSOs)

Operational experience is essential — FPSO HAZOPs should never be purely desk-based.

Step 3: Collect and Review HAZOP Inputs

Key documents required include:

- PFDs and P&IDs

- Cause and Effect charts

- Process control narratives

- Equipment data sheets

- Layout drawings

- Previous HAZOP reports

- Incident and near-miss data

All documents must reflect the current as-operated configuration of the FPSO.

Step 4: Define Nodes for FPSO Systems

A node is a manageable section of the process selected for review.

Typical FPSO HAZOP nodes include:

- Inlet manifolds

- First-stage separators

- Compression trains

- Crude oil export pumps

- Produced water treatment systems

- Fuel gas systems

- Flare and vent systems

Nodes should be small enough for detailed analysis but large enough to maintain process context.

Step 5: Apply Guidewords and Identify Deviations

Guidewords are systematically applied to each parameter.

Common HAZOP Guidewords:

| Guideword | Meaning |

|---|---|

| No | Complete absence |

| More | Higher than intended |

| Less | Lower than intended |

| Reverse | Opposite direction |

| As well as | Additional presence |

| Other than | Different composition |

Example Deviation:

More Pressure in Separator

Step 6: Identify Causes and Consequences

For each deviation, the team identifies:

Possible Causes

- Control valve failure

- Blocked outlet

- Instrument malfunction

- Human error

- Power failure

Potential Consequences

- Vessel overpressure

- Hydrocarbon release

- Fire or explosion

- Equipment damage

- Production shutdown

FPSO-specific escalation paths (e.g. confined spaces, marine exposure) must be considered.

Step 7: Review Existing Safeguards

Safeguards may include:

- Pressure relief valves (PRVs)

- Safety Instrumented Functions (SIFs)

- Alarms and operator response

- Physical barriers

- Emergency shutdown (ESD) systems

- Operating procedures

Each safeguard is assessed for effectiveness and independence.

Step 8: Identify Recommendations and Actions

When safeguards are inadequate, the team raises recommendations such as:

- Additional instrumentation or alarms

- Changes to control logic

- Improved procedures

- Design modifications

- Operator training

Recommendations should be:

- Clear

- Actionable

- Risk-based

Step 9: Assign Actions and Track Closure

All HAZOP actions must be:

- Assigned to responsible persons

- Risk-ranked

- Tracked to closure

- Verified for effectiveness

Unclosed HAZOP actions represent residual risk and must be managed under Management of Change (MOC).

Common FPSO HAZOP Pitfalls to Avoid

- Treating HAZOP as a paperwork exercise

- Inadequate operations participation

- Poor node definition

- Over-reliance on alarms as safeguards

- Failure to close out actions

- Not revalidating HAZOPs over time

HAZOP vs Other FPSO Risk Assessment Tools

| Tool | Purpose |

|---|---|

| HAZOP | Systematic deviation analysis |

| LOPA | Semi-quantitative risk evaluation |

| Bow-Tie | Visual barrier management |

| FMEA | Component-level failure analysis |

| QRA | Quantitative risk modeling |

HAZOP often serves as the foundation for these other analyses.

Best Practices for Effective FPSO HAZOP Studies

- Use an independent, experienced facilitator

- Combine engineering knowledge with operational insight

- Integrate lessons learned from incidents

- Link HAZOP outcomes to barrier management systems

- Digitize action tracking for accountability

- Periodically revalidate studies

Conclusion

HAZOP studies remain a cornerstone of process safety management on FPSOs. When properly planned, facilitated, and followed through, HAZOPs provide powerful insights into how offshore process systems can fail — and how to prevent catastrophic outcomes.

For FPSO operators, engineers, and HSSE professionals, a robust HAZOP process is not just a regulatory requirement — it is a critical defense against major accidents and operational failures.

Frequently Asked Questions (FAQs)

How often should FPSO HAZOPs be revalidated?

Typically every 5 years or following significant process changes or incidents.

Who owns HAZOP actions on an FPSO?

The asset owner or operator is responsible, with actions managed under MOC and integrity systems.

Can HAZOP be done on existing FPSOs?

Yes. Operational and revalidation HAZOPs are common and essential for aging assets.

Related Topics:

- Layers of Protection Analysis (LOPA) for FPSOs

- Bow-Tie Risk Analysis for FPSO Major Accident Hazards

- Safety Critical Elements (SCEs) on FPSOs

Pingback: Layers of Protection Analysis (LOPA) for FPSO Systems: A Practical Offshore Guide - HSSE Tips

Pingback: Bow-Tie Risk Analysis for FPSO Major Accident Hazards: A Practical Offshore Guide - HSSE Tips

Pingback: Safety Critical Elements (SCEs) on FPSOs: Identification, Performance Standards, and Assurance - HSSE Tips

Pingback: Inherent Safety in FPSO Design and Retrofit Projects: Reducing Risk at the Source - HSSE Tips

Pingback: FPSO Process Safety Incident Case Studies and Lessons Learned: Preventing Major Offshore Accidents - HSSE Tips