Floating Production, Storage and Offloading units (FPSOs) operate in a high-hazard environment where a single failure can escalate into catastrophic consequences. Fires, explosions, hydrocarbon releases, and loss of containment events on FPSOs are classified as Major Accident Hazards (MAHs) due to their potential for multiple fatalities, severe environmental damage, and asset loss.

To effectively understand, control, and communicate these risks, offshore operators increasingly rely on Bow-Tie Risk Analysis — a visual and structured method that links hazards, preventive barriers, mitigative controls, and escalation factors in a single, easy-to-understand framework.

This article explains how Bow-Tie Risk Analysis is applied to FPSO major accident hazards, why it is so effective offshore, and how it integrates with HAZOP, LOPA, and barrier management systems.

What Is Bow-Tie Risk Analysis?

Bow-Tie Risk Analysis is a risk assessment and visualization technique that combines:

- Fault Tree thinking (what can go wrong)

- Event Tree thinking (what happens if it does)

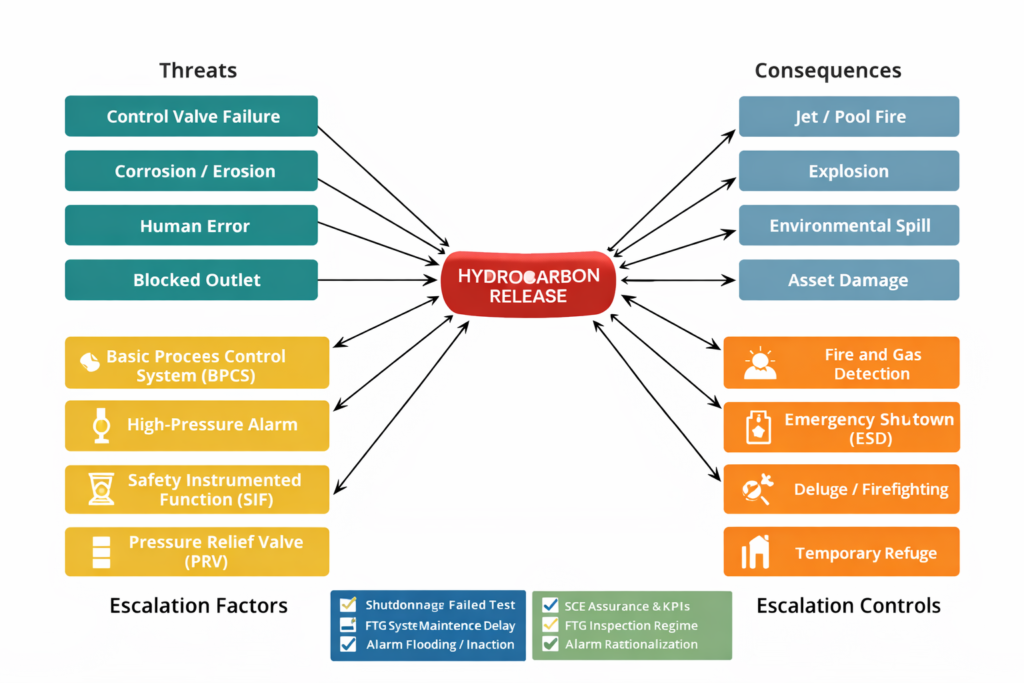

The diagram resembles a bow-tie:

- The hazard sits at the center

- Threats appear on the left

- Consequences appear on the right

- Preventive barriers stop threats

- Mitigative barriers reduce consequences

Bow-Tie analysis does not replace detailed calculations — it organizes and communicates risk control strategies clearly, which is essential for complex FPSO operations.

Why Bow-Tie Analysis Is Ideal for FPSOs

FPSOs benefit significantly from Bow-Tie analysis because it:

- Simplifies complex offshore risks into visual logic

- Links engineering, operational, and human barriers

- Supports regulatory demonstration of risk control

- Strengthens barrier management systems

- Improves workforce understanding of MAHs

- Aligns well with Safety Case and ALARP principles

On FPSOs, where space is limited and operations are continuous, clarity and visibility of safety barriers are critical.

Understanding Major Accident Hazards (MAHs) on FPSOs

Typical FPSO MAHs include:

- Loss of containment of hydrocarbons

- Fire and explosion on topsides

- Turret or offloading system failure

- Overpressure of process vessels

- Gas release in confined spaces

- Collision or offloading hose rupture

Bow-Tie analysis helps demonstrate how each MAH is prevented and mitigated.

Structure of a Bow-Tie Diagram for FPSOs

1. Hazard

The hazard is the source of potential harm.

FPSO Example:

Large inventory of pressurized hydrocarbons on topsides

2. Top Event

The top event is the moment control of the hazard is lost.

Example:

Uncontrolled hydrocarbon release from a separator

3. Threats (Left Side)

Threats are events that could cause the top event.

FPSO Threat Examples:

- Control valve failure

- Corrosion or erosion

- Instrument malfunction

- Human error during maintenance

- Blocked outlet or line rupture

- Power failure

Each threat should be realistic and credible.

4. Preventive Barriers

Preventive barriers stop threats from leading to the top event.

Typical FPSO Preventive Barriers:

- Basic Process Control System (BPCS)

- High-pressure alarms

- Safety Instrumented Functions (SIFs)

- Pressure Relief Valves (PRVs)

- Operating procedures

- Competency and training

Bow-Tie analysis tests whether these barriers are effective, independent, and maintained.

5. Consequences (Right Side)

Consequences describe what happens if the top event occurs.

FPSO Consequence Examples:

- Jet fire or vapor cloud explosion

- Fatalities or serious injuries

- Environmental pollution

- Production shutdown

- Asset damage or loss

6. Mitigative Barriers

Mitigative barriers reduce the severity of consequences.

FPSO Mitigation Examples:

- Emergency Shutdown (ESD) systems

- Fire and gas detection

- Deluge and firefighting systems

- Passive fire protection

- Emergency response procedures

- Temporary refuge and evacuation systems

7. Escalation Factors and Controls

Escalation factors are conditions that could weaken barriers.

Examples:

- Poor maintenance

- Inadequate testing

- Alarm flooding

- Fatigue or manning shortages

- SIMOPS conflicts

Each escalation factor should have escalation controls, such as inspections, audits, or management systems.

Step-by-Step Bow-Tie Development for FPSOs

Step 1: Select a Major Accident Scenario

Typically derived from HAZOP or LOPA studies.

Step 2: Define the Hazard and Top Event

Be specific and operationally meaningful.

Step 3: Identify Credible Threats

Use historical incidents and offshore experience.

Step 4: Map Preventive Barriers

Focus on independence and performance standards.

Step 5: Define Consequences

Consider personnel, environment, asset, and reputation.

Step 6: Identify Mitigative Barriers

Verify emergency response capability offshore.

Step 7: Test Barrier Effectiveness

Link barriers to inspections, KPIs, and assurance activities.

Relationship Between Bow-Tie, HAZOP, and LOPA

Bow-Tie analysis integrates seamlessly with other FPSO risk tools:

| Tool | Role |

|---|---|

| HAZOP | Identifies deviations and hazards |

| LOPA | Evaluates adequacy of protection layers |

| Bow-Tie | Visualizes barriers and escalation |

| Barrier Management | Ensures ongoing effectiveness |

HAZOP identifies what can go wrong, LOPA evaluates how much protection is enough, and Bow-Tie shows how risks are controlled day-to-day.

Common Bow-Tie Mistakes on FPSOs

- Treating Bow-Tie as a one-time exercise

- Including too many weak or non-independent barriers

- Failing to manage escalation factors

- Poor linkage to maintenance and inspection systems

- Not involving operations personnel

- Lack of ownership for barrier assurance

Best Practices for Effective FPSO Bow-Tie Analysis

- Align Bow-Ties with Safety Critical Elements (SCEs)

- Link barriers to maintenance and testing regimes

- Use Bow-Ties in training and toolbox talks

- Regularly update Bow-Ties after changes or incidents

- Integrate with Management of Change (MOC)

- Digitize Bow-Tie management for tracking

Regulatory and Safety Case Relevance

Bow-Tie analysis supports:

- Safety Case demonstrations

- ALARP justification

- Barrier assurance frameworks

- Regulatory audits and inspections

- Corporate process safety governance

Many regulators expect operators to clearly demonstrate barrier control of MAHs, and Bow-Ties provide this clarity.

Conclusion

Bow-Tie Risk Analysis is a powerful and practical tool for managing major accident hazards on FPSOs. By clearly linking threats, barriers, consequences, and escalation factors, Bow-Tie diagrams help offshore teams understand not just what the risks are, but how they are controlled.

When integrated with HAZOP, LOPA, and barrier management systems, Bow-Tie analysis becomes a cornerstone of effective FPSO process safety management.

Related Articles & Further Reading

To deepen your understanding of FPSO process safety and risk management, explore these related guides:

- FPSO Hazard & Operability Studies (HAZOP): Step-by-Step Guide

- Layers of Protection Analysis (LOPA) for FPSO Systems

- Process Safety and Barrier Management on FPSOs

- Safety Instrumented Systems (SIS) Explained for Offshore Operations

- Overpressure Protection Systems Explained