Overpressure incidents are among the most dangerous events in industrial operations. When pressure exceeds equipment design limits, the result can be violent rupture, explosions, fires, toxic releases, and multiple fatalities.

To prevent such outcomes, industries rely on Overpressure Protection Systems (OPS)—a combination of engineering controls, instrumentation, and safety devices designed to keep pressure within safe limits.

This HSSETips.com guide explains overpressure protection systems, how they work, why they fail, and how HSSE professionals can manage them effectively across the asset lifecycle.

What Is Overpressure?

Overpressure occurs when the pressure inside equipment exceeds its Maximum Allowable Working Pressure (MAWP) or design limits.

Common Causes of Overpressure

- Blocked outlet or closed valve

- Control valve failure

- Fire exposure (external heating)

- Thermal expansion of trapped liquid

- Chemical reactions

- Compressor or pump malfunction

HSSE principle:

Overpressure is often sudden, silent, and unforgiving.

What Is an Overpressure Protection System (OPS)?

An Overpressure Protection System is any system designed to:

- Prevent pressure from exceeding safe limits, or

- Relieve excess pressure safely when prevention fails

OPS is a critical safety barrier in process safety management.

Why Overpressure Protection Is Critical in HSSE

Failure of overpressure protection has caused major industrial disasters, including:

- Pressure vessel ruptures

- Jet fires and BLEVE events

- Pipeline failures

- Offshore explosions

HSSE insight:

Most pressure equipment failures are survivable only if overpressure protection works as designed.

Types of Overpressure Protection Systems

Overpressure protection is achieved using multiple layers of defense, including:

1. Inherent and Design-Based Protection

These are passive measures built into the system design.

Examples

- Proper material selection

- Adequate wall thickness

- Design margins

- Pressure-rated components

These measures reduce likelihood, but cannot eliminate all overpressure scenarios.

2. Instrumented Overpressure Protection (IOP)

Pressure Control Systems

- Pressure transmitters

- Control valves

- Automatic pressure regulation

These systems:

- Maintain normal operating pressure

- Respond quickly to deviations

⚠️ HSSE limitation:

Control systems are not safety systems and may fail.

3. Safety Instrumented Systems (SIS)

SIS provides automatic shutdown when pressure reaches dangerous levels.

Typical SIS Actions

- Close shutdown valves

- Stop pumps or compressors

- Isolate pressure sources

HSSE rule:

SIS is a preventive barrier, not a pressure relief device.

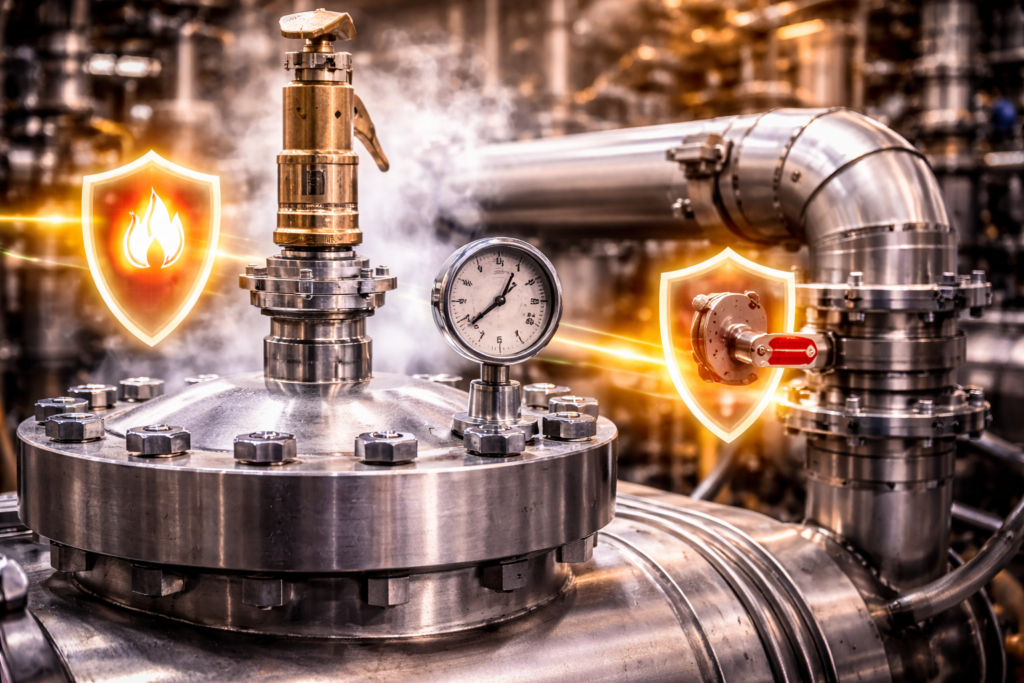

4. Pressure Relief Devices (PRDs)

Pressure Relief Devices provide the final line of defense against overpressure.

Common Types

- Pressure Safety Valves (PSVs)

- Safety Relief Valves (SRVs)

- Rupture Discs

These devices physically release pressure to protect equipment.

Pressure Safety Valves (PSVs) Explained

A PSV automatically opens at a preset pressure and discharges fluid to prevent pressure buildup.

Key Characteristics

- Mechanical and independent

- No external power required

- Opens rapidly at set pressure

HSSE Note

PSVs are often the only barrier protecting equipment during fire exposure.

Rupture Discs Explained

A rupture disc is a thin membrane designed to burst at a specific pressure.

Advantages

- Instant full opening

- No moving parts

- Suitable for corrosive service

Limitations

- Single-use device

- No reseating capability

Often used in combination with PSVs.

Layers of Protection Concept (LOPA)

Overpressure protection should follow the Layers of Protection approach:

- Inherent design

- Basic process control

- Alarms and operator response

- Safety Instrumented Systems

- Pressure relief devices

- Emergency response

HSSE principle:

No single barrier should be relied upon alone.

Common Overpressure Scenarios (HSSE Focus)

Blocked Outlet

- Valve closed downstream

- Pressure rises rapidly

Fire Case

- External fire heats vessel

- Internal pressure increases due to vaporization

Thermal Expansion

- Liquid trapped between closed valves

- Small temperature rise causes large pressure increase

Overpressure Protection in Oil & Gas and FPSOs

Critical OPS applications include:

- Separators and pressure vessels

- Compressors and pipelines

- Produced water systems

- Chemical injection skids

- Export and offloading systems

Offshore environments demand:

- High reliability

- Corrosion resistance

- Redundant protection

Inspection, Testing, and Maintenance of OPS

OPS effectiveness depends on:

- Regular PSV testing

- Verification of set pressures

- Inspection of discharge paths

- Removal of isolation valves

- Proper documentation

HSSE rule:

A blocked or isolated relief valve is equivalent to no relief valve.

Common HSSE Failures in Overpressure Protection

❌ Relief valves isolated or gagged

❌ Incorrect PSV sizing

❌ Discharge to unsafe locations

❌ Outdated relief calculations

❌ Poor inspection regimes

Many incidents occur because relief devices were present but ineffective.

Standards and Regulations Governing OPS

Key international standards include:

- API RP 521 – Pressure-relieving systems

- ASME Section VIII – Pressure vessels

- ISO 4126 – Safety valves

- IEC 61511 – SIS

- Pressure Equipment Regulations (PED / PSSR)

HSSETips.com recommends strict compliance with applicable local and international regulations.

Roles and Responsibilities in Overpressure Protection

Engineers

- Design and size OPS correctly

- Conduct relief calculations

HSSE Professionals

- Verify barrier integrity

- Audit OPS effectiveness

- Track impairments

Operations

- Never isolate relief devices

- Report abnormal pressure conditions

Practical HSSE Example

Scenario: Fire Case Overpressure

- Vessel exposed to pool fire

- Pressure rises rapidly

- PSV lifts and discharges safely

Without PSV:

- Vessel ruptures

- Explosion and fire escalate

Lesson:

Relief devices save lives only when properly designed and maintained.

Conclusion

Overpressure Protection Systems are fundamental to process safety. They protect equipment, people, and the environment from some of the most severe industrial hazards.

For HSSE professionals, understanding OPS is not optional—it is essential for:

- Major accident prevention

- Regulatory compliance

- Barrier management effectiveness

Overpressure protection is the difference between a controlled event and a catastrophe.

Frequently Asked Questions (FAQs)

Is a pressure control valve enough for overpressure protection?

No. Control systems can fail and must not be relied upon alone.

Are PSVs mandatory?

In most pressure systems, yes—especially where credible overpressure scenarios exist.

Can SIS replace a relief valve?

No. SIS prevents overpressure; relief valves protect when prevention fails.

How often should relief valves be tested?

Based on regulations and risk—typically every 1–5 years.

Internal Linking Suggestions for HSSETips.com

- 👉 Pressure Equipment Safety Regulations

- 👉 Safety Instrumented Systems (SIS) Explained

- 👉 Process Safety and Barrier Management

- 👉 How to Select Pressure Instruments for Safety-Critical Systems