Accurate pressure measurement is a cornerstone of health, safety, security, and environmental (HSSE) performance. Yet one of the most misunderstood topics in industrial instrumentation is the difference between pressure gauge errors and pressure transmitter accuracy.

In safety-critical environments—such as oil and gas facilities, FPSOs, refineries, power plants, and manufacturing sites—this misunderstanding can lead to missed alarms, delayed shutdowns, and serious incidents.

This HSSETips.com guide explains the difference clearly, using real operational examples and industry best practices to help safety professionals, engineers, and supervisors make informed decisions.

Why Pressure Measurement Accuracy Matters in HSSE

Pressure is often a leading indicator of risk, especially in:

- Process vessels and separators

- Boilers and steam systems

- Hydraulic and pneumatic systems

- Firewater and deluge systems

- Chemical injection and dosing skids

Incorrect pressure readings can result in:

- Overpressure incidents

- Equipment failure

- Loss of containment

- Environmental releases

- Personnel injuries

Understanding instrument limitations is therefore a core HSSE competence.

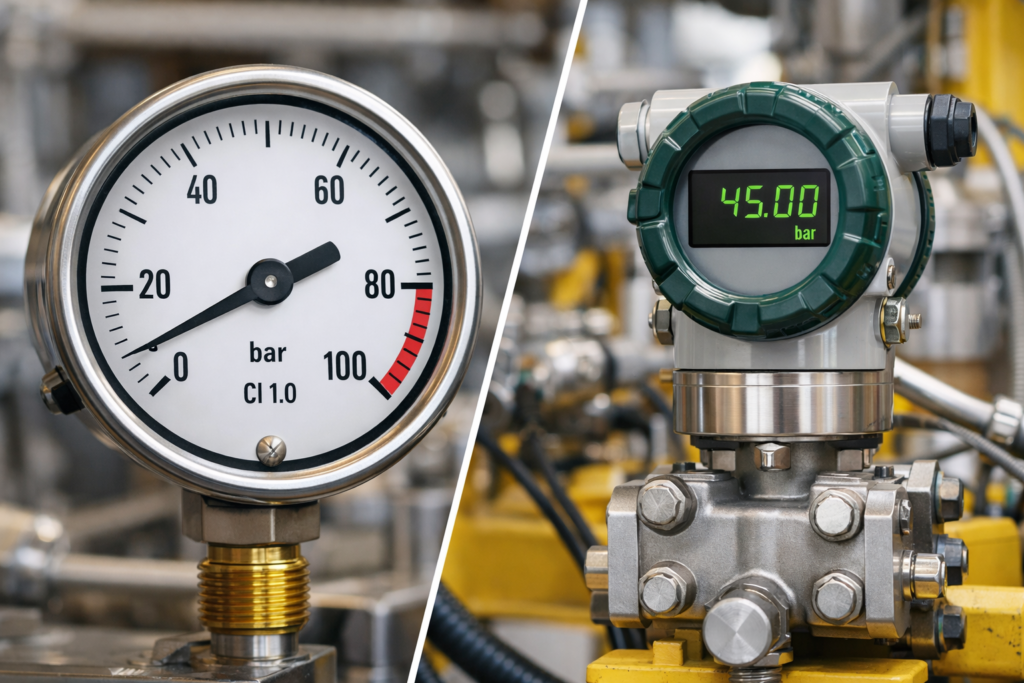

Understanding Pressure Gauges

A pressure gauge is a mechanical instrument that displays pressure locally using a dial and pointer. Common sensing elements include:

- Bourdon tubes

- Diaphragms

- Bellows

Pressure gauges are widely used because they are simple, rugged, and inexpensive.

Pressure Gauge Accuracy and Error Explained

How Gauge Accuracy Is Defined

Pressure gauge accuracy is expressed as a percentage of full scale (FS) and indicated by an accuracy class such as:

- CI 2.5

- CI 1.6

- CI 1.0

CI 1.0 means the gauge can deviate by ±1% of its full-scale range at any point on the dial.

Pressure Gauge Error Example

- Gauge range: 0–100 bar

- Accuracy class: CI 1.0

- Maximum error: ±1 bar

| Gauge Reading | Actual Pressure Could Be |

|---|---|

| 10 bar | 9–11 bar |

| 50 bar | 49–51 bar |

| 90 bar | 89–91 bar |

⚠️ Important:

Gauge error is constant across the scale, not proportional to the reading.

Common Sources of Pressure Gauge Errors

Mechanical pressure gauges are affected by several operational factors:

1. Mechanical Hysteresis

Readings differ when pressure is rising versus falling.

2. Wear and Aging

Internal gears and linkages degrade over time, reducing accuracy.

3. Vibration and Pulsation

Common near pumps and compressors, causing needle oscillation and damage.

4. Temperature Effects

Thermal expansion affects Bourdon tube elasticity.

5. Zero Shift

The pointer fails to return to zero after depressurization.

Limitations of Pressure Gauges in Safety-Critical Systems

Pressure gauges:

- Are not suitable for control loops

- Cannot reliably trigger alarms or trips

- Have limited long-term accuracy

- Provide local indication only

- Are unsuitable for SIL-rated functions

HSSE takeaway:

Pressure gauges are indicative instruments, not safety instruments.

Understanding Pressure Transmitters

A pressure transmitter is an electronic instrument that converts pressure into an electrical signal such as:

- 4–20 mA

- HART

- Modbus

- Foundation Fieldbus

Transmitters send accurate pressure data to DCS, PLC, or SIS systems.

Pressure Transmitter Accuracy Explained

How Transmitter Accuracy Is Specified

Pressure transmitter accuracy is typically expressed as:

- ±% of span, or

- ±% of reading

Accuracy specifications often include:

- Linearity

- Hysteresis

- Repeatability

- Temperature compensation

Pressure Transmitter Accuracy Example

- Range: 0–100 bar

- Accuracy: ±0.1% of span

- Maximum error: ±0.1 bar

This accuracy remains consistent across the operating range.

Advantages of Pressure Transmitters in HSSE Systems

Pressure transmitters offer:

- High accuracy and repeatability

- Excellent long-term stability

- Automatic temperature compensation

- Digital calibration and diagnostics

- Remote monitoring capability

- Alarm and shutdown integration

- Suitability for Safety Instrumented Systems (SIS)

HSSE takeaway:

Transmitters are designed for process control and risk reduction.

Gauge Errors vs Transmitter Accuracy: HSSE Comparison Table

| Feature | Pressure Gauge | Pressure Transmitter |

|---|---|---|

| Accuracy basis | % of full scale | % of span / reading |

| Typical accuracy | ±1.6% to ±2.5% FS | ±0.5% to ±0.05% |

| Long-term drift | High | Low |

| Temperature compensation | Minimal | Advanced |

| Vibration resistance | Limited | High |

| Signal output | Visual only | 4–20 mA / digital |

| Control loop use | ❌ No | ✅ Yes |

| Alarm & trip use | ❌ No | ✅ Yes |

| SIL suitability | ❌ No | ✅ Yes |

Real-World HSSE Example: FPSO Separator Pressure

- Normal operating pressure: 45 bar

- High-pressure alarm setpoint: 50 bar

Using a CI 1.6 Pressure Gauge (0–100 bar)

- Error: ±1.6 bar

- Actual pressure may reach 50 bar while gauge shows 48.4 bar

- ⚠️ Alarm may not activate in time

Using a Pressure Transmitter (±0.1% accuracy)

- Error: ±0.1 bar

- Alarm activates precisely at 50 bar

- ✅ Improved process safety

HSSE Best Practice Rule

Pressure gauges are for people. Pressure transmitters are for systems.

Use Pressure Gauges for:

- Local visual indication

- Maintenance verification

- Field inspection reference

Use Pressure Transmitters for:

- Process control (PLC / DCS)

- Alarms and trips

- Safety Instrumented Functions

- Performance monitoring and trending

Common HSSE Misconception

❌ “The gauge shows 50 bar, so the pressure is exactly 50 bar.”

✅ “The gauge shows approximately 50 bar within its allowable error.”

This misunderstanding has contributed to numerous near-misses and incidents across industries.

Conclusion

Pressure gauges and pressure transmitters are not interchangeable. Gauges provide approximate, local indication, while transmitters deliver accurate, stable data essential for process control and safety systems.

For HSSE professionals, understanding this difference is critical to:

- Preventing overpressure incidents

- Ensuring alarm reliability

- Protecting people, assets, and the environment

Frequently Asked Questions (FAQs)

Is a pressure gauge accurate enough for safety alarms?

No. Pressure gauges are not suitable for alarms, trips, or safety systems.

Why is gauge accuracy based on full scale?

Mechanical limitations make gauge error constant across the entire range.

Can a gauge replace a transmitter?

No. Gauges are indicators; transmitters are measurement and control devices.

Which instrument should be used for SIS applications?

Only certified pressure transmitters should be used for Safety Instrumented Systems.

Related Topics:

- 👉 What Does HSSE Stand For?

- 👉 Process Safety and Barrier Management

- 👉 Permit to Work (PTW) Systems Explained

- 👉 Pressure Equipment Safety Regulations