Stop Work Authority (SWA) is one of the most powerful human safety barriers in modern HSSE management systems. In high-risk offshore environments such as Floating Production Storage and Offloading units (FPSOs)—especially during Turnaround Maintenance (TAM), shutdowns, and complex SIMOPS—SWA plays a decisive role in preventing major accidents, injuries, and catastrophic process safety events.

Despite advanced engineering controls, procedures, and permit systems, history shows that many offshore incidents escalated because unsafe work was allowed to continue. Stop Work Authority exists to prevent exactly that.

This article explains what Stop Work Authority is, why it is essential for FPSO process safety, and how it should be effectively applied during offshore operations and TAM activities.

What Is Stop Work Authority?

Stop Work Authority (SWA) is the formal right and responsibility of every worker—regardless of role or seniority—to stop any task or operation they believe is unsafe.

SWA empowers individuals to intervene immediately when:

- Hazards are not adequately controlled

- Conditions differ from what was planned or risk-assessed

- Barriers are missing, degraded, or failing

- There is uncertainty about the safety of an activity

If work is not safe, it must not continue—no matter the schedule or production pressure.

Stop Work Authority as a Process Safety Barrier

In FPSO operations, SWA functions as a critical human barrier within the broader Process Safety and Barrier Management framework.

Relationship to Process Safety

Stop Work Authority:

- Prevents loss of containment events

- Interrupts unsafe pathways before escalation

- Compensates for temporary or degraded technical barriers

- Supports defence-in-depth principles

- Aligns with bow-tie risk models as an escalation prevention control

In many offshore accidents, investigations revealed that someone recognised the danger—but felt unable to stop the job. SWA eliminates that hesitation.

Why Stop Work Authority Is Critical in FPSO Operations

FPSOs operate with:

- High hydrocarbon inventories

- Pressurised and high-temperature systems

- Simultaneous production and maintenance activities

- Constrained spaces and complex interfaces

During TAM and shutdown phases, risk exposure increases significantly due to:

- Large contractor workforce

- Non-routine tasks

- Temporary equipment and bypasses

- Frequent permit changes

- Increased lifting, hot work, and confined space entries

SWA becomes the last reliable barrier when procedures, supervision, or conditions fail.

When Should Stop Work Authority Be Exercised Offshore?

Stop Work Authority should be used whenever a worker believes continuing the task could lead to harm.

Typical FPSO Scenarios Requiring SWA

- Lockout/Tagout not fully applied or verified

- Conflicting SIMOPS activities

- Permit conditions not matching site reality

- Unsafe scaffolding or lifting arrangements

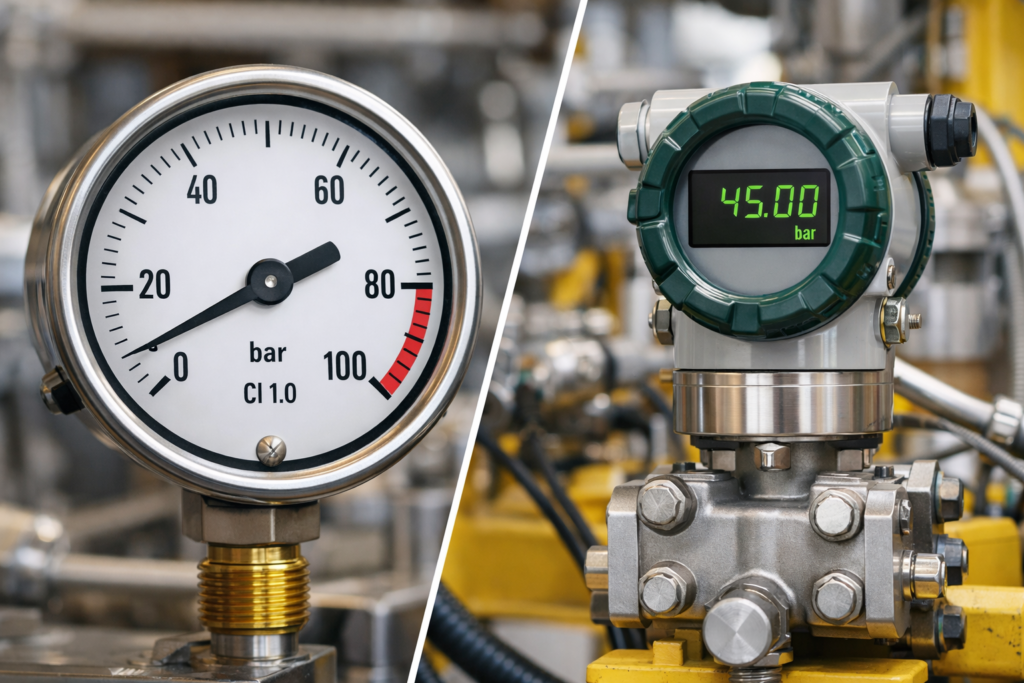

- Unexpected pressure, leaks, or abnormal readings

- Gas detection alarms or unexplained smells

- Weather deterioration affecting lifting or deck work

- Workers unclear about the task or sequence

- Fatigue, rushed work, or production pressure

Using SWA is not a failure—it is evidence of a strong safety culture.

Stop Work Authority During FPSO Turnaround Maintenance (TAM)

Turnaround Maintenance presents some of the highest process safety risks offshore.

Why SWA Is Vital During TAM

- Multiple contractors with varying safety cultures

- Rapid task sequencing and compressed schedules

- Temporary isolations and system reinstatements

- Increased hot work and confined space entries

- High potential for miscommunication

During TAM, SWA should be:

- Actively promoted during toolbox talks

- Reinforced by supervisors and OIMs

- Supported without blame or retaliation

- Logged and reviewed for learning

The Stop Work Authority Process (Best Practice)

A consistent and simple SWA process improves confidence and effectiveness.

Step 1: STOP

Immediately pause the task safely.

Step 2: COMMUNICATE

Clearly explain the concern to the team or supervisor.

Step 3: ASSESS

Review hazards using:

- Job Hazard Analysis (JHA)

- Permit to Work (PTW)

- Toolbox talk discussion

- SIMOPS review

Step 4: CONTROL

Implement effective controls:

- Engineering

- Procedural

- Administrative

- PPE (as last line)

Step 5: RESUME

Restart work only after agreement that risks are controlled.

Leadership and Safety Culture: The Backbone of SWA

Stop Work Authority only works when leadership genuinely supports it.

Effective FPSO leadership ensures:

- No retaliation for good-faith SWA use

- Supervisors thank workers who stop unsafe work

- SWA events are reviewed as learning opportunities

- Production pressure never overrides safety

A culture that discourages SWA is a leading indicator of future incidents.

Common Barriers to Using Stop Work Authority Offshore

Despite policy statements, workers may hesitate due to:

- Fear of being blamed or labelled “difficult”

- Contractor pressure to meet deadlines

- Poor supervisor reactions in the past

- Cultural or hierarchical barriers

- Normalisation of deviance

Addressing these requires visible leadership commitment and continuous reinforcement.

Stop Work Authority and Regulatory Expectations

SWA aligns with:

- Offshore safety case principles

- Barrier management expectations

- Major accident hazard (MAH) controls

- International oil and gas HSSE standards

Regulators increasingly view SWA as a key indicator of workforce engagement in safety.

Integrating SWA Into FPSO Process Safety Systems

For effective implementation:

- Embed SWA in PTW and TAM procedures

- Include SWA scenarios in training and drills

- Link SWA to bow-tie and barrier assurance

- Track SWA usage trends (not for punishment)

- Share lessons learned across assets

Recommended Safety Essentials for Offshore and TAM Operations

(Check availability and suitability for your worksite before purchase)

- 🔧 Lockout/Tagout Devices and Tags – Widely available industrial LOTO kits help ensure proper isolation during maintenance tasks.

- 🦺 Flame-Resistant Coveralls (FR) – Certified FR clothing provides essential protection during hot work and process operations.

- 🧤 Cut-Resistant Safety Gloves – Designed to reduce hand injuries during mechanical and maintenance activities.

- 🪖 Certified Hard Hats with Chin Straps – Suitable for offshore deck work and lifting operations.

- 🧯 Portable Gas Detectors – Personal multi-gas monitors support early hazard identification offshore.

(Always follow your company’s approved PPE and equipment standards.)

Conclusion

Stop Work Authority is not just a policy statement—it is a life-saving process safety barrier. In FPSO operations and Turnaround Maintenance, where complexity, pressure, and risk intersect, SWA often makes the difference between safe execution and major accident escalation.

A workforce that understands, trusts, and actively uses Stop Work Authority is one of the strongest indicators of a mature offshore safety culture.

If it’s not safe, stop the work.

If you’re unsure, stop the work.

If something doesn’t feel right—stop the work.

Suggested Links for Further Reading

- FPSO Process Safety Fundamentals

- Barrier Management and Bow-Tie Analysis

- Permit to Work Systems on FPSOs

- SIMOPS Risk Management Offshore

- Turnaround Maintenance Safety on FPSOs