When Focus Becomes a Hazard

In high-risk industries such as oil & gas, chemical processing, power generation, and offshore FPSO operations, focus is often praised as a virtue. However, excessive or misdirected focus can become a serious safety liability. This phenomenon is known as attentional tunneling—a cognitive condition where individuals become so narrowly focused on a specific task, alarm, or objective that they fail to perceive other critical information.

Attentional tunneling has contributed to numerous process safety incidents, near misses, and catastrophic accidents. Understanding this hidden human-factors risk is essential for preventing barrier failure, improving situational awareness, and strengthening operational resilience.

This article explains what attentional tunneling is, why it occurs, how it impacts process safety, and practical strategies to prevent it in complex industrial environments.

What Is Attentional Tunneling?

Attentional tunneling is a cognitive state in which an individual’s attention becomes excessively narrowed, causing them to miss important cues, alarms, or changes in their environment.

In process safety contexts, this often manifests as:

- Operators fixating on one alarm while ignoring others

- Engineers focusing on production targets while overlooking deviations

- Supervisors concentrating on a single task during abnormal situations

Unlike simple distraction, attentional tunneling is often driven by stress, workload, time pressure, and alarm overload—conditions common in major accident hazard (MAH) industries.

Why Attentional Tunneling Occurs in High-Risk Operations

1. High Cognitive Load

Control rooms, FPSO decks, and processing plants often demand simultaneous monitoring of multiple parameters. When cognitive capacity is exceeded, the brain prioritizes one stream of information and suppresses others.

2. Stress and Time Pressure

During upsets, emergencies, or production losses, stress hormones impair peripheral awareness, increasing the likelihood of tunnel vision.

3. Alarm Floods and Poor HMI Design

Excessive alarms or poorly designed Human-Machine Interfaces (HMI) force operators to focus on the loudest or most visually dominant alert—often not the most critical one.

4. Task Fixation and Goal Conflict

Strong emphasis on output, uptime, or troubleshooting a single fault can unintentionally suppress broader hazard awareness.

Attentional Tunneling vs Normal Focus

It is important to distinguish healthy focus from hazardous attentional tunneling:

| Healthy Focus | Attentional Tunneling |

|---|---|

| Situationally aware | Context-blind |

| Flexible attention | Rigid fixation |

| Prioritizes safety | Ignores competing risks |

| Adjusts with feedback | Persists despite warning signs |

In process safety, rigid fixation is dangerous, especially during abnormal operations.

How Attentional Tunneling Impacts Process Safety

Barrier Degradation

Operators may unknowingly bypass or overlook critical safety barriers, such as interlocks, alarms, or procedural steps.

Missed Early Warning Signs

Small deviations—pressure trends, temperature drift, vibration changes—can be missed, allowing hazards to escalate unchecked.

Delayed Emergency Response

Tunnel vision slows recognition of escalating scenarios, increasing response time during fires, gas releases, or loss of containment events.

Normalisation of Deviation

Repeated focus on “making it work” instead of “keeping it safe” gradually shifts risk acceptance thresholds.

Real-World Process Safety Scenarios Involving Attentional Tunneling

- Control Room Operations: An operator fixates on restoring a single pump while missing a rising pressure trend upstream

- FPSO Production Upsets: Focus on maintaining oil output blinds teams to abnormal gas system behavior

- Maintenance Activities: Technicians concentrate on task completion and overlook simultaneous operations (SIMOPS) hazards

- Emergency Situations: Alarm floods cause attention to lock onto non-critical alarms while critical ones are ignored

These patterns are repeatedly identified in major accident investigations.

Relationship to Other Process Safety Concepts

Attentional tunneling is closely linked to:

- Operational Drift

- Ostrich Effect

- Loss of Situational Awareness

- Human-Machine Interface (HMI) Failures

- Swiss Cheese Model Barrier Alignment

Together, these human-factor risks form a common precursor to major accidents.

Preventing Attentional Tunneling in Process Safety Systems

1. Alarm Management and Rationalisation

Implement alarm prioritisation, shelving, and clear escalation logic to reduce cognitive overload.

👉 Recommended Tool

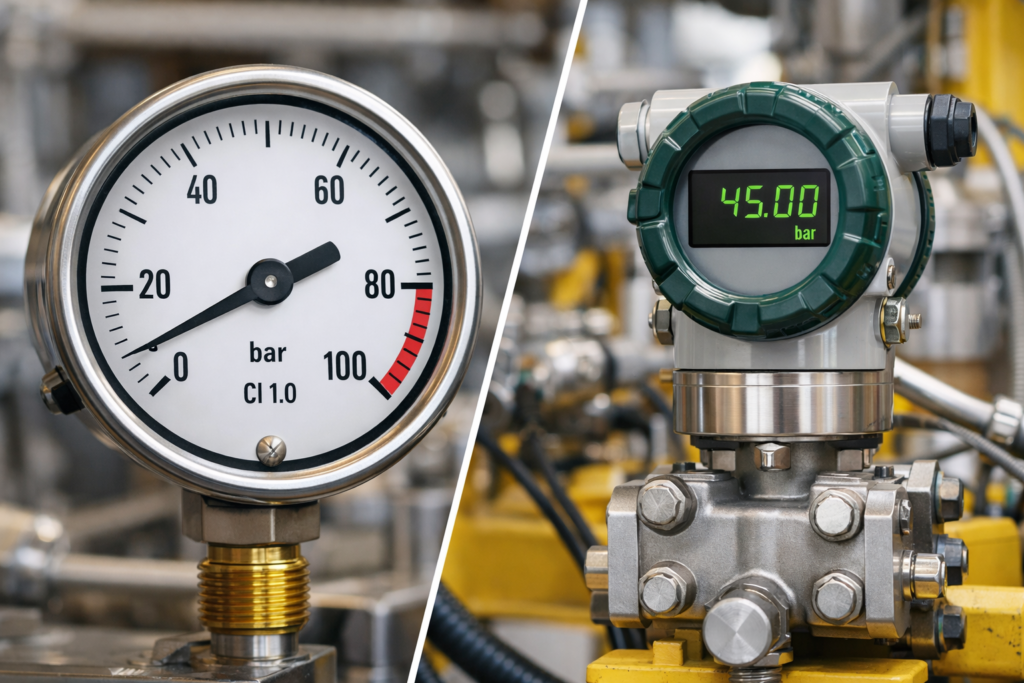

Industrial alarm indicators and audible warning devices help differentiate critical alerts from nuisance alarms.

🔧 Check current prices for industrial alarm indicators and safety annunciators on Amazon

2. Human-Centred HMI Design

Design displays that emphasize:

- Trends over single values

- Visual hierarchy

- Clear abnormal situation cues

Well-designed interfaces reduce fixation risk.

3. Procedural Discipline and Cross-Checks

Mandatory pause points, peer verification, and challenge-response protocols help break cognitive tunneling.

👉 Recommended Resource

Laminated abnormal operations checklists and control room reference cards support structured thinking under pressure.

📋 View durable industrial safety checklists and control room aids on Amazon

4. Training on Cognitive Bias and Human Factors

Explicit training on attentional tunneling helps workers recognize when their focus is becoming unsafe.

Key training topics should include:

- Cognitive overload

- Stress effects on perception

- Situational awareness recovery techniques

5. Leadership and Safety Culture

Supervisors must reinforce that “stopping to reassess” is a safety strength, not a weakness. Production pressure should never override hazard awareness.

Toolbox Talk Summary: Attentional Tunneling

Key Message:

“If you’re too focused on one thing, you may be missing the real danger.”

Ask the Team:

- What other risks might I be missing right now?

- Have conditions changed since we last assessed the task?

- Is my focus helping safety—or harming it?

Encouraging these questions prevents fixation and supports safe decision-making.

FAQs

Is attentional tunneling a human error?

Not exactly. It is a predictable cognitive limitation, often triggered by system design and organizational pressures.

Can procedures eliminate attentional tunneling?

Procedures help, but training, design, and culture are equally important.

Is attentional tunneling relevant offshore?

Yes. FPSOs and offshore installations are particularly vulnerable due to alarm density, SIMOPS, and high workload environments.

Conclusion: Managing Attention Is Managing Risk

Attentional tunneling is a silent but powerful contributor to process safety failures. Left unaddressed, it erodes barriers, delays response, and allows small deviations to escalate into major accidents.

By improving alarm management, HMI design, training, and leadership behaviors, organizations can protect workers from the limits of human attention—and build safer, more resilient operations.

Related Topics:

- Process Safety Fundamentals

- Operational Drift in High-Risk Industries

- Alarm Management Best Practices

- Human Factors in Process Safety

- FPSO Process Safety Case Studies