Operational drift is one of the most underestimated threats to workplace safety—particularly in high-risk environments such as FPSOs, offshore installations, and industrial workshops. Unlike obvious rule violations, operational drift develops slowly and quietly, eroding safety margins until a serious incident occurs.

This article explains what operational drift is, why it happens, how it affects FPSO operations and tools & equipment safety, and practical HSSE strategies to detect and control it before it leads to incidents.

What Is Operational Drift?

Operational drift is the gradual deviation from approved procedures, standards, and safe operating limits during routine work.

Over time, small informal changes in how work is performed become normalized, even though they may increase risk.

Operational drift occurs when “work as done” slowly moves away from “work as imagined.”

This phenomenon is widely recognized in process safety, human factors engineering, and major accident prevention frameworks.

Why Operational Drift Happens

Operational drift is rarely intentional. It usually emerges from systemic pressures rather than individual misconduct.

Common Causes of Operational Drift

- Production pressure and time constraints

- Complacency from repeated success

- Ineffective supervision or assurance

- Outdated or impractical procedures

- Poor training or skills fade

- Informal workarounds becoming permanent

In FPSO environments, long campaigns, repetitive tasks, and rotating crews increase the likelihood of drift if not actively managed.

Operational Drift vs. Unsafe Acts

It is important to distinguish operational drift from deliberate violations.

| Aspect | Operational Drift | Unsafe Act / Violation |

|---|---|---|

| Intent | Usually unintentional | Often deliberate |

| Speed | Gradual, incremental | Immediate |

| Visibility | Hard to detect | Easily noticeable |

| Culture | Normalized over time | Known rule-breaking |

Operational drift is more dangerous because it hides in plain sight.

Operational Drift in FPSO Operations

FPSOs operate within tight safety envelopes where multiple barriers must work together. Drift weakens these barriers one step at a time.

Common FPSO Examples

- Permit-to-Work steps being simplified or skipped

- SIMOPS controls informally relaxed

- Temporary operating limits treated as permanent

- Alarm response times increasing gradually

- Safety Critical Element (SCE) testing reduced in rigor

Over time, these deviations accumulate, increasing the likelihood of a major accident event (MAE).

Many offshore disasters were not caused by sudden failures—but by years of unmanaged drift.

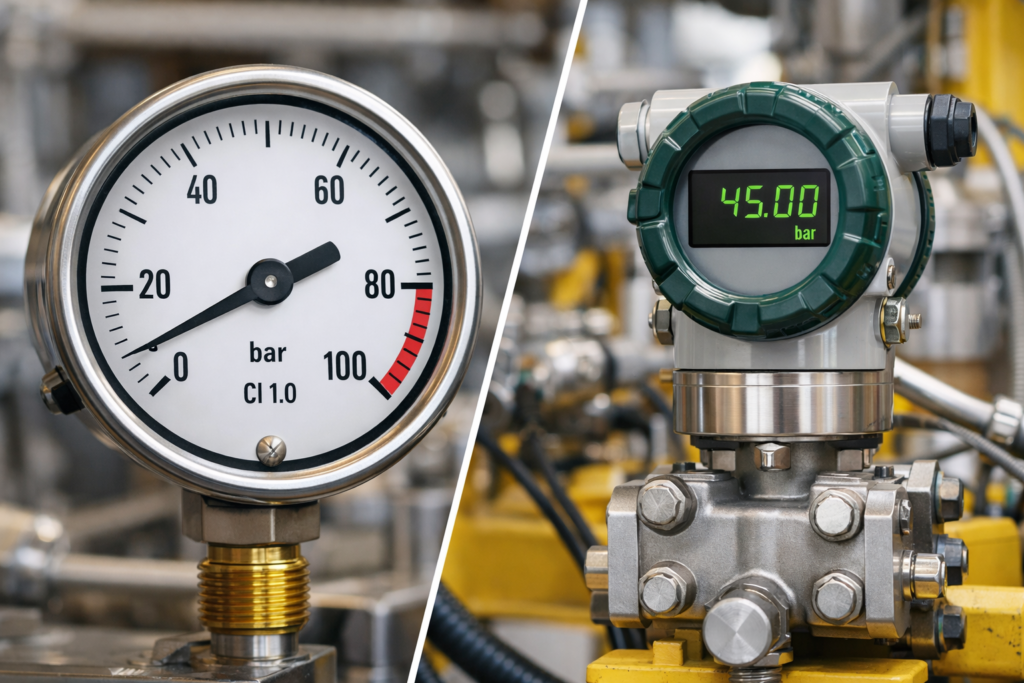

Operational Drift in Tools and Equipment Safety

Operational drift also significantly affects hand tools, power tools, and equipment safety, especially in workshops and maintenance activities.

Typical Tool Safety Drift

- Using damaged tools “just for this job”

- Skipping functional checks before use

- Using incorrect tools to save time

- PPE standards gradually relaxed

- Calibration intervals extended informally

These behaviors often feel harmless—until a serious injury or equipment failure occurs.

Link to Major Accident Models

Operational drift is clearly illustrated by established safety models:

Swiss Cheese Model

- Each layer of defense develops small weaknesses

- Drift enlarges these weaknesses

- Eventually, the holes align and an incident occurs

Bow-Tie Risk Model

- Drift weakens preventive barriers

- Recovery barriers may still exist—but with reduced effectiveness

Warning Signs of Operational Drift

HSSE professionals and supervisors should watch for early indicators:

- “We’ve always done it this way”

- Increased reliance on workarounds

- Procedures rarely consulted

- Declining quality of toolbox talks

- Near misses becoming normalized

- Reduced reporting of deviations

Early detection is critical.

How to Control and Prevent Operational Drift

Preventing operational drift requires system-level controls, not blame.

1. Strengthen Field Presence

- Conduct meaningful safety walks

- Observe real work—not paperwork

- Ask workers why tasks are done a certain way

2. Keep Procedures Realistic

- Regularly review and update procedures

- Align procedures with actual working conditions

- Involve frontline workers in revisions

3. Use Management of Change (MoC)

- Capture informal changes

- Assess risk before changes become normalized

- Apply MoC to both technical and operational changes

4. Reinforce Safety Culture

- Encourage speaking up

- Reward early reporting

- Focus on learning, not punishment

5. Monitor Safety Critical Activities

- Pay special attention to:

- Permit-to-Work systems

- SIMOPS

- Lifting operations

- Tool and equipment inspections

- SCE performance standards

Practical HSSE Tools to Support Drift Control

The right equipment supports consistent, compliant behavior.

Recommended Safety Products:

- Industrial safety inspection checklists and logbooks

Check availability of durable inspection logbooks suitable for offshore and workshop use on Amazon. - Ergonomic, certified hand tools

Explore ergonomically designed hand tools that meet industrial safety standards—available on Amazon. - Lockout/Tagout kits

Consider standardized Lockout/Tagout kits designed for maintenance and equipment isolation, available through Amazon. - High-visibility PPE and cut-resistant gloves

View a selection of certified PPE suitable for offshore and industrial environments on Amazon.

(As an Amazon Associate, we may earn from qualifying purchases.)

Role of Leadership in Managing Operational Drift

Leadership behavior strongly influences whether drift is corrected or reinforced.

Effective leaders:

- Ask uncomfortable questions

- Challenge “normal” unsafe practices

- Allocate time for safe execution

- Demonstrate visible commitment to standards

What leaders tolerate today becomes tomorrow’s standard.

Key Takeaways

- Operational drift is gradual, silent, and systemic

- It affects both FPSO operations and tools & equipment safety

- Most major incidents have drift in their background

- Early detection and system-level controls are essential

- Strong leadership and realistic procedures are critical

Related Topics:

- FPSO Operations and Process Safety

- Permit to Work (PTW) Systems on FPSOs

- SIMOPS Management Offshore

- Tools and Equipment Safety

- Hand Tools Inspection and Maintenance

- Human Factors in Workplace Safety