Despite advanced engineering controls, automated systems, and robust safety procedures, human error remains a major contributor to offshore incidents. On Floating Production, Storage and Offloading units (FPSOs), where operations are complex, continuous, and high-risk, the interaction between people, systems, and the working environment plays a decisive role in safety performance.

This is where Human Factors (HF) and Human Reliability Analysis (HRA) become critical.

Human Factors focuses on designing systems that support human performance, while HRA systematically evaluates the likelihood of human error and its impact on safety. Together, they form an essential pillar of modern FPSO process safety and major accident prevention.

This article explains how Human Factors and HRA are applied in FPSO operations, why they matter, and how they integrate with HAZOP, LOPA, Bow-Tie analysis, and Safety Critical Elements (SCEs).

What Are Human Factors?

Human Factors is the discipline that examines how humans interact with:

- Equipment and technology

- Procedures and tasks

- Work environment

- Organizational systems

The goal is to optimize human performance and reduce the likelihood of error, particularly in high-risk industries like offshore oil and gas.

In FPSO safety, Human Factors ensures that systems are designed for real human behavior, not idealized assumptions.

What Is Human Reliability Analysis (HRA)?

Human Reliability Analysis (HRA) is a structured method used to:

- Identify safety-critical human actions

- Assess the likelihood of human error

- Understand factors influencing performance

- Quantify or qualitatively rank human error probability

HRA answers a key process safety question:

How likely is it that a human action will fail when it is needed to protect against a major accident?

Why Human Factors and HRA Are Critical on FPSOs

FPSOs operate under conditions that increase the likelihood of human error:

- 24/7 operations and shift work

- Fatigue and circadian rhythm disruption

- Complex control rooms and alarm systems

- Confined spaces and harsh offshore environments

- SIMOPS and time-critical decisions

- Emergency response under stress

On FPSOs, a single incorrect action or delayed response can defeat multiple engineering barriers. Human Factors and HRA help prevent this.

Common Human Error Types in FPSO Operations

Human errors are typically grouped into three categories:

1. Slips and Lapses

Unintended actions, often due to:

- Fatigue

- Distraction

- Poor interface design

Example: Opening the wrong valve due to poor labeling.

2. Mistakes

Errors in decision-making caused by:

- Inadequate knowledge

- Incorrect mental models

- Poor procedures

Example: Misinterpreting process conditions during startup.

3. Violations

Deliberate deviations from procedures, often driven by:

- Time pressure

- Production demands

- Normalization of deviation

Example: Bypassing alarms to maintain production.

Human Factors in FPSO System Design

Human Factors principles should be embedded in FPSO design and operations, including:

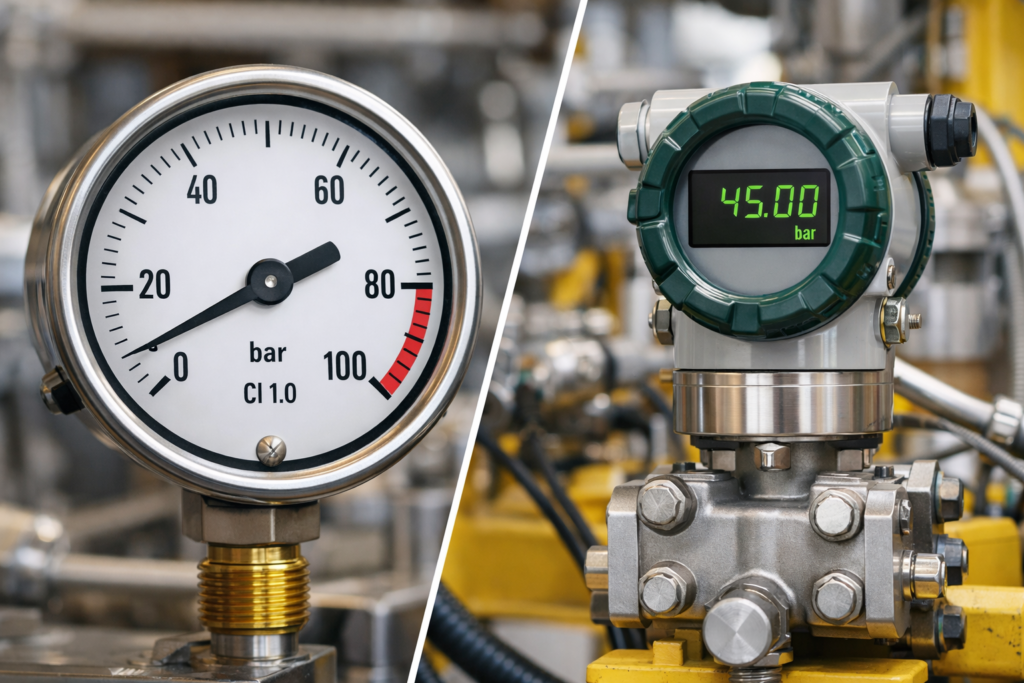

Control Room Design

- Clear layout and line of sight

- Consistent color coding

- Logical alarm prioritization

- Minimized alarm flooding

Equipment and Layout

- Accessible valves and instruments

- Safe maintenance access

- Clear labeling and tagging

Procedures

- Simple, task-focused procedures

- Clear decision points

- Alignment with actual operations

Good design prevents error rather than relying on perfect behavior.

Human Reliability Analysis (HRA) Methods Used Offshore

Several HRA techniques are applied in FPSO safety studies, including:

THERP (Technique for Human Error Rate Prediction)

- Quantifies human error probabilities

- Commonly used in detailed risk assessments

HEART (Human Error Assessment and Reduction Technique)

- Semi-quantitative

- Practical for engineering and operations teams

SPAR-H

- Widely used in high-hazard industries

- Considers performance shaping factors (PSFs)

FPSO operators often apply simplified HRA within LOPA and Bow-Tie analyses.

Human Factors in HAZOP, LOPA, and Bow-Tie Studies

In HAZOP

Human actions are examined as:

- Causes of deviations

- Safeguards (operator response to alarms)

In LOPA

Human actions may be credited as Independent Protection Layers (IPLs) — but only if reliability can be justified.

In Bow-Tie Analysis

Human actions appear as:

- Preventive barriers (e.g. correct valve operation)

- Mitigative barriers (e.g. emergency response)

HRA helps ensure that human barriers are realistic and defensible.

Human Factors and Safety Critical Elements (SCEs)

Many SCEs depend on human performance, including:

- Manual ESD activation

- Emergency response procedures

- Permit to Work (PTW) systems

- Firefighting and evacuation actions

Human Factors ensures that people-dependent SCEs are supported by training, ergonomics, and procedures, while HRA assesses their reliability.

Performance Shaping Factors (PSFs) on FPSOs

HRA evaluates Performance Shaping Factors, such as:

- Fatigue and workload

- Training and competence

- Stress and time pressure

- Quality of procedures

- Interface design

- Environmental conditions

Poor PSFs significantly increase the likelihood of error — even among experienced crews.

Managing Human Factors Risk on FPSOs

Effective FPSO human performance management includes:

- Fatigue risk management systems

- Alarm management and rationalization

- Competency and training assurance

- Strong safety culture

- Clear communication during SIMOPS

- Human-centered MOC reviews

- Learning from incidents and near misses

Human Factors must be treated as a core safety discipline, not a soft topic.

Common Human Factors Pitfalls Offshore

- Assuming procedures alone prevent error

- Over-crediting operator response in risk studies

- Poor alarm design and overload

- Inadequate shift handover

- Ignoring fatigue and mental workload

- Blaming individuals instead of systems

Best Practices for Human Factors and HRA on FPSOs

- Integrate Human Factors early in design

- Use HRA selectively for high-risk scenarios

- Treat human actions as safety barriers with performance standards

- Link human-dependent barriers to training and audits

- Involve operators in risk studies

- Review human performance after incidents

- Promote a just and learning safety culture

Regulatory and Safety Case Expectations

Regulators increasingly expect FPSO operators to demonstrate that:

- Human factors are systematically considered

- Human error risks are identified and managed

- Operator actions credited in risk studies are justified

- Safety-critical human tasks are trained and assured

Human Factors and HRA therefore support Safety Case compliance and ALARP demonstrations.

Conclusion

On FPSOs, people are an integral part of the safety system. Human Factors ensures that systems are designed to support human performance, while Human Reliability Analysis provides a structured way to understand and manage human error risk.

When properly integrated with engineering controls, barrier management, and safety leadership, Human Factors and HRA significantly reduce the likelihood of major accidents offshore and strengthen overall FPSO process safety.

Related Articles & Further Reading

To deepen your understanding of FPSO process safety and barrier management, explore these related guides:

- FPSO Hazard & Operability Studies (HAZOP): Step-by-Step Guide

- Layers of Protection Analysis (LOPA) for FPSO Systems

- Bow-Tie Risk Analysis for FPSO Major Accident Hazards

- Safety Critical Elements (SCEs) on FPSOs

- Process Safety and Barrier Management on FPSOs

- Managing Cyber-Physical Risk in Offshore Safety Systems