Introduction

Personal Protective Equipment (PPE) is one of the most visible symbols of workplace safety. Hard hats, safety boots, gloves, respirators, goggles, and coveralls are often the first things people associate with “being safe at work.” Many organizations proudly display signs that say “No PPE, No Work.”

But here’s the critical question every safety professional must ask:

Is PPE alone enough to keep workers safe?

The honest, professional answer is no.

While PPE is essential, it is not sufficient on its own. Relying solely on PPE creates a false sense of security and leaves workers exposed to serious risks. This article explains why PPE has limits, where it fits in effective safety management, and what truly keeps workers safe.

What Is PPE and What Is It Designed to Do?

Personal Protective Equipment refers to wearable items designed to protect workers from specific hazards when exposure cannot be fully eliminated.

Common Types of PPE

- Head protection (helmets, hard hats)

- Eye and face protection (goggles, face shields)

- Hearing protection (earplugs, earmuffs)

- Respiratory protection (dust masks, respirators)

- Hand protection (cut-resistant, chemical-resistant gloves)

- Body protection (coveralls, flame-resistant clothing)

- Foot protection (safety boots, anti-slip shoes)

What PPE Is Meant to Do

- Reduce severity of injury, not eliminate the hazard

- Act as a last line of defense

- Protect individuals, not systems

PPE does not remove danger—it only reduces the consequences when something goes wrong.

Why PPE Alone Is Not Enough

1. PPE Is the Last Line of Defense

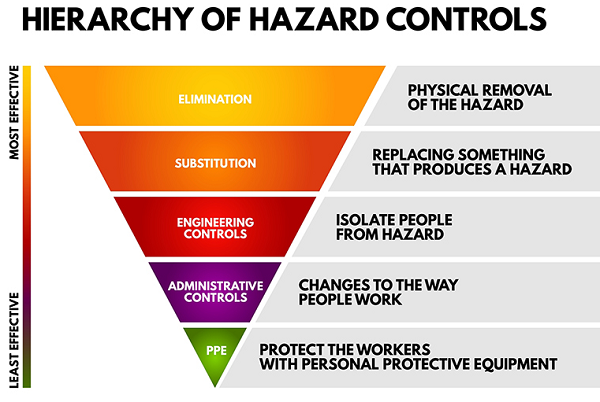

In professional safety practice, PPE sits at the bottom of the Hierarchy of Controls. This hierarchy ranks risk-control methods from most effective to least effective:

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- Personal Protective Equipment (PPE)

PPE is used only when higher-level controls cannot fully manage the risk.

If PPE is your primary control, it means:

- Hazards still exist

- Failure leads directly to injury

2. PPE Depends on Human Behavior

PPE effectiveness relies heavily on people doing the right thing, every time.

Common human-factor failures include:

- PPE not worn at all

- PPE worn incorrectly

- PPE removed for comfort

- Wrong PPE selected

- PPE not maintained or replaced

Even well-trained workers:

- Get tired

- Become complacent

- Take shortcuts under pressure

Safety systems that rely purely on perfect human behavior will eventually fail.

3. PPE Does Not Prevent Accidents

PPE does not stop:

- Falls from height

- Machinery entanglement

- Explosions

- Structural collapse

- Chemical releases

It may reduce injury severity, but the incident still happens.

Example:

- A helmet may reduce head injury

- It does not stop an object from falling

True safety focuses on preventing the event, not just surviving it.

4. PPE Has Physical and Technical Limits

PPE is not invincible.

Examples:

- Respirators fail if not properly fitted

- Gloves tear or degrade

- Hearing protection loses effectiveness over time

- PPE becomes contaminated

- Heat stress increases with heavy PPE

In harsh environments (oil & gas, mining, construction, offshore operations), PPE can even introduce new risks such as:

- Heat exhaustion

- Reduced visibility

- Restricted movement

5. Over-Reliance on PPE Encourages Poor Safety Culture

When PPE is treated as the main safety solution, organizations may:

- Ignore unsafe equipment design

- Accept hazardous processes

- Delay engineering improvements

- Shift responsibility from management to workers

This creates a dangerous mindset:

“As long as you wear PPE, the job is safe.”

In reality:

If PPE is your main control, the job is already unsafe.

Where PPE Fits in a Strong Safety System

PPE is necessary, but it must be part of a layered defense strategy.

Effective Safety = Multiple Layers of Protection

1. Elimination

- Remove the hazard completely

- Example: design out working at height

2. Substitution

- Replace with something less hazardous

- Example: use low-toxicity chemicals

3. Engineering Controls

- Isolate people from danger

- Example: machine guards, barriers, ventilation

4. Administrative Controls

- Manage exposure through systems

- Procedures, permits, training, supervision

5. PPE

- Protect against residual risk only

When PPE is used correctly on top of other controls, it becomes highly effective.

Real-World Examples

Example 1: Noise Exposure

- ❌ PPE only: Earplugs

- ✅ Better approach:

- Quiet equipment selection

- Acoustic enclosures

- Shift rotation

- Hearing protection as backup

Example 2: Chemical Handling

- ❌ PPE only: Gloves and respirator

- ✅ Better approach:

- Closed transfer systems

- Automated dosing

- Local exhaust ventilation

- PPE for residual exposure

Example 3: Working at Height

- ❌ PPE only: Helmet and harness

- ✅ Better approach:

- Eliminate height work

- Install permanent platforms

- Guardrails

- PPE as last protection

Why PPE Still Matters

Despite its limitations, PPE is non-negotiable in many workplaces.

PPE:

- Saves lives when other controls fail

- Reduces injury severity

- Protects against unforeseen events

- Acts as a visible safety reminder

The key is not overestimating its power.

The Professional Safety Message

PPE does not make work safe.

PPE makes unsafe work survivable.

A mature safety system:

- Controls hazards at the source

- Designs safety into equipment and processes

- Supports workers with systems, not slogans

- Uses PPE as a final protective layer

Conclusion: Is PPE Enough to Keep Workers Safe?

No. PPE alone is not enough.

PPE is:

- Essential ✔

- Necessary ✔

- Life-saving ✔

- But insufficient on its own ❌

True worker safety comes from:

- Hazard elimination

- Thoughtful design

- Strong engineering controls

- Clear procedures

- Effective supervision

- Positive safety culture

- And PPE as the last line of defense

If you want real safety, don’t ask:

“Are workers wearing PPE?”

Ask instead:

“Why do they still need it?”

Final Thought

The safest workplaces are not the ones with the most PPE—they are the ones with the least need for it.